The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Top 10 Industrial Packaging Equipment Solutions for Efficient Operations

In today’s rapidly evolving industrial landscape, the demand for efficient operations is more critical than ever. One of the pivotal components in achieving this efficiency is the utilization of advanced industrial packaging equipment. As companies strive to enhance productivity and streamline processes, the integration of innovative packaging solutions has emerged as a vital strategy. This article delves into the top 10 industrial packaging equipment solutions that can transform operational workflows, reduce waste, and optimize overall performance.

The variety of industrial packaging equipment available reflects the diverse needs of different sectors. From automated systems that enhance speed and accuracy to eco-friendly options that support sustainability goals, these solutions are designed to meet the challenges of modern manufacturing and distribution. Understanding the benefits and functionalities of various industrial packaging equipment not only empowers businesses to make informed investment decisions but also prepares them to adapt to the ever-changing market demands. As we explore these top solutions, we highlight their significance in achieving operational excellence and maintaining a competitive edge in the industry.

Industrial Packaging Equipment: An Overview of Its Importance

Industrial packaging equipment plays a pivotal role in modern manufacturing and logistics operations. By streamlining the packaging process, companies can enhance productivity, reduce waste, and maintain product integrity. Efficient packaging solutions not only ensure timely delivery but also contribute to sustainability goals by minimizing packaging materials and optimizing space in transportation. This is increasingly important as industries strive to meet consumer demands and regulatory standards.

Tips for optimizing your industrial packaging operations include investing in automation technology, which can significantly reduce manual labor and human error. Implementing a regular maintenance schedule for your equipment is essential to prevent downtime and costly repairs. Additionally, staying informed about the latest packaging trends and materials can help your business adapt to changing market needs and customer preferences, ensuring that you remain competitive in an ever-evolving landscape.

Incorporating effective training programs for your staff on the use of packaging equipment can enhance efficiency and safety. This not only helps in operating the machines correctly but also empowers your team to identify potential issues before they escalate, creating a more proactive work environment. Engaging employees in the packaging process fosters a sense of ownership and can lead to innovative solutions that further improve operational efficiency.

Top 10 Industrial Packaging Equipment Solutions for Efficient Operations

| Equipment Type | Key Features | Efficiency Benefits | Typical Applications |

|---|---|---|---|

| Automated Packing Machines | Speed, accuracy, and reduced labor costs | Increased throughput and lower operational costs | Food and beverage, electronics |

| Stretch Wrappers | Consistent wrapping tension, high output | Protection during transit, reduced material costs | Palletized goods |

| Case Packers | Versatile case handling, minimal manual intervention | Higher packing speed, reduced labor costs | Beverages, consumer goods |

| Bags and Pouch Fillers | Flexible packaging, quick changeover | Reduced waste, improved shelf life | Snack foods, powders |

| Labeling Equipment | Automated, precise labeling | Enhanced branding, compliance with regulations | Pharmaceuticals, food products |

| Shrink Wrappers | Robust sealing, high-speed operation | Product protection, improved aesthetics | Consumer goods, trays |

| Conveyor Systems | Modular design, adjustable speeds | Streamlined operations, reduced handling time | All manufacturing sectors |

| Filling Machines | Accurate volume control, various product compatibility | Reduced spillage, consistent quality | Liquids, powders, granules |

| Carton Sealers | Automated sealing, adjustable height | Increased throughput, reduced labor | E-commerce, food packaging |

| Palletizing Systems | Robotic and conventional options | Maximized space utilization, labor savings | Warehouse, shipping |

Key Features of Efficient Industrial Packaging Solutions

Efficient industrial packaging solutions are essential in streamlining operations and reducing costs. One key feature of these solutions is automation. By incorporating advanced machinery that automates the packaging process, companies can significantly enhance throughput and minimize labor costs. Automated systems can quickly adjust to different packaging formats, ensuring a smooth transition between product lines, which is crucial for meeting fluctuating demand. This adaptability not only increases efficiency but also reduces the likelihood of human error in packaging.

Another important aspect of efficient industrial packaging is the use of smart technology. Integrating IoT devices and smart sensors allows for real-time monitoring of packaging operations. This level of insight empowers manufacturers to make data-driven decisions to optimize processes, predict maintenance needs, and reduce downtime. Furthermore, effective tracking and traceability features enhance inventory management and ensure compliance with industry regulations, thus improving overall operational efficiency. Together, these features create a robust packaging strategy that supports sustainable and efficient industrial practices.

Top 10 Industrial Packaging Equipment Solutions for Efficient Operations

Types of Industrial Packaging Equipment for Various Applications

In today’s fast-paced industrial landscape, the choice of packaging equipment is critical to ensuring efficient operations across various sectors. The diversity in applications means that selecting the right type of equipment can greatly impact productivity and operational costs. According to a report by Freedonia Group, the demand for industrial packaging machinery is projected to reach $24 billion by 2024, highlighting the importance of innovation and efficiency in packaging solutions.

Among the different types of industrial packaging equipment, automatic and semi-automatic systems have gained popularity due to their ability to enhance throughput while reducing labor costs. For instance, filling machines are essential for accurately dispensing products into containers, and advancements in technology have increased their precision and speed. Additionally, case packaging machinery is critical for preparing products for shipping, with recent market analyses indicating that the adoption of robotic solutions in this space can decrease packaging cycle times by up to 20%.

Moreover, wrapping and labeling machines also play a significant role in improving supply chain efficiency. They not only ensure that products are securely packed but also enhance traceability and compliance with regulations. The 2022 Packaging Machinery Market Report noted that companies employing advanced wrapping solutions experience an upward trend, with a 15% boost in operational efficiency. As industries continue to adapt to the evolving demands of the market, investing in versatile and efficient packaging equipment remains essential for maintaining competitive advantage.

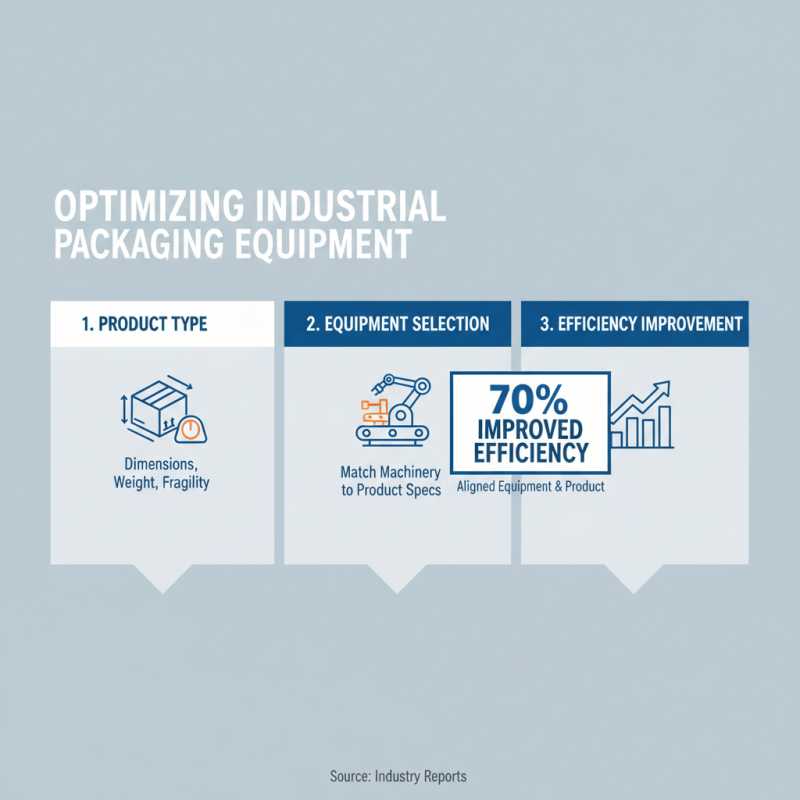

Factors to Consider When Choosing Packaging Equipment

When selecting the right industrial packaging equipment, several key factors must be taken into account to ensure efficient operations. First and foremost is the type of products being packaged. Companies need to evaluate the dimensions, weight, and fragility of their products, as these characteristics will dictate the machinery required. According to industry reports, 70% of businesses that align their equipment choices with their product specifications see a marked improvement in their packing efficiency.

Another critical consideration is the production volume. High-speed packaging lines demand equipment that can keep pace with output requirements. A recent market analysis indicated that industries capable of increasing their package throughput by just 20% could save upwards of 15% in operational costs. This underscores the importance of choosing equipment that not only meets current needs but is also adaptable for future scaling.

**Tip:** When assessing packaging solutions, engage with suppliers who provide customization options. This allows for the integration of specific features that cater to unique operational requirements.

Finally, it’s vital to consider the ease of operation and maintenance of the packaging equipment. Complex machinery can lead to increased downtime and operational disruptions. Industry insights highlight that simpler equipment with user-friendly interfaces typically experiences 30% less unplanned downtime compared to their more complicated counterparts.

**Tip:** Invest in training for your team to ensure they are well-versed in operating the equipment efficiently. Proper training can enhance productivity and prolong the life of your packaging machinery.

Future Trends in Industrial Packaging Equipment Technology

As the industrial sector continues to evolve, so do the technologies that support efficient packaging solutions. Future trends in industrial packaging equipment are leaning toward automation, sustainability, and smart technology integration. Companies are increasingly adopting automated systems that enhance speed and reduce labor costs. Machine learning and artificial intelligence are being integrated into packaging lines, allowing for more precise control and predictive maintenance, which can significantly reduce downtime.

Tip: When considering new packaging equipment, evaluate the level of automation that aligns with your operational needs. A fully automated system may not be required for all businesses, and a balance between manual and automated processes can often lead to better results.

Sustainability is another major trend influencing industrial packaging technology. Organizations are focusing on eco-friendly materials and practices to appeal to environmentally conscious consumers. Innovations in biodegradable and recyclable materials are becoming more prevalent, and companies are investing in equipment that minimizes waste during the packaging process.

Tip: Invest time in researching materials that not only suit your packaging needs but also contribute to sustainability goals. Collaborating with suppliers who share a commitment to reducing environmental impact can benefit your brand and operational efficiency.

Related Posts

-

How to Choose the Right Industrial Packaging Equipment for Your Business

-

Top 10 Industrial Food Packaging Machines for Your Production Line

-

How to Implement Food Packaging Automation for Maximum Efficiency and Cost Savings

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management

-

10 Essential Tips for Choosing the Right Case Packer for Your Business