The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Top 10 Industrial Packaging Equipment You Must Consider for Your Business

In today's competitive market, the importance of efficient and reliable industrial packaging equipment cannot be overstated. As businesses strive to optimize their operations and reduce costs, the right packaging solutions can significantly enhance productivity and packaging integrity. According to John Smith, a renowned expert in the industrial packaging equipment sector, "Investing in the right packaging machinery is not just a choice; it's a necessity for businesses looking to scale and meet consumer demand effectively."

With the myriad of options available, selecting the ideal equipment can be daunting. From automated fillers to advanced sealing machines, understanding the various types and their applications becomes crucial for any enterprise. In this guide, we will explore the top 10 industrial packaging equipment options that every business should consider to enhance their operational efficiency and improve product protection. By staying updated with technological advancements and industry trends, businesses can make informed decisions that align with their unique packaging needs.

Types of Industrial Packaging Equipment for Different Industries

When selecting industrial packaging equipment, it's essential to consider the specific needs of different industries. For the food and beverage sector, machinery that offers high-speed packaging along with sanitation features is critical. Often, this includes vacuum sealing machines and automated bottling lines that ensure products remain fresh and safe for consumption. In pharmaceuticals, precision and compliance are paramount; thus, labeling and sealing equipment that meets regulatory standards is often necessary to guarantee product integrity.

In sectors like manufacturing and logistics, the choice of packaging equipment might focus on efficiency and durability. Heavy-duty packing machines, stretch wrapping systems, and strapping machines are commonly employed to ensure that products are securely packaged and protected during transport. Additionally, companies in e-commerce increasingly rely on automated packaging systems that streamline the packing process, reducing labor costs while improving speed and accuracy. By understanding the different types of industrial packaging equipment tailored for each sector, businesses can enhance their operational efficiency and meet their specific packaging needs effectively.

Top 10 Industrial Packaging Equipment Usage by Industry

This bar chart shows the usage rate of various types of industrial packaging equipment across different industries. The Food & Beverages sector leads the way, illustrating its significant reliance on specialized packaging solutions.

Key Features to Look for in Packaging Machinery

When selecting industrial packaging equipment for your business, it's crucial to focus on key features that enhance efficiency and meet your production needs. First and foremost, consider the machinery's versatility. The ability to adapt to different packaging formats and materials is essential, as it allows for greater flexibility in response to changing market demands. Additionally, look for equipment that offers easy changeovers between different packaging styles, which can help maintain productivity without significant downtime.

Another important feature is automation capabilities. Advanced packaging machinery equipped with automated functions can significantly reduce manual labor, minimize errors, and increase output. Features such as programmable settings and integration with other systems can streamline operations and improve overall efficiency. Furthermore, pay attention to the machine's build quality and maintenance requirements. Durable materials and designs that allow for easy cleaning and servicing will ensure long-term reliability and minimal disruptions to your production line. Overall, choosing the right packaging equipment with these key features can greatly influence the success of your packaging operations.

Benefits of Automating Your Packaging Process

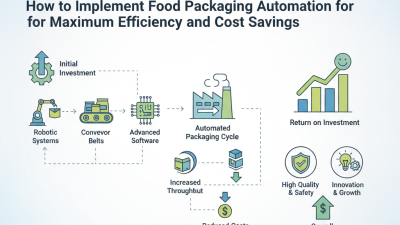

In today's fast-paced production environments, automating the packaging process is essential for businesses aiming to enhance efficiency and reduce costs. Research indicates that companies that invest in automation can achieve up to a 30% increase in productivity. Automation minimizes human error, reduces labor costs, and significantly speeds up the packaging process, enabling businesses to respond quickly to market demands.

Integrating automated packaging equipment, such as robotic arms and advanced wrapping machines, can also lead to better consistency in packaging quality. According to a report by the Freedonia Group, automation in packaging could save businesses approximately $10,000 annually per employee through improved efficiency. These technological advancements not only streamline operations but also elevate workplace safety, as automated systems can handle heavier and more hazardous tasks.

Tips: When considering automation, assess your current packaging needs and future scalability. Start with a pilot program to evaluate the impact on your production line, and ensure your team is adequately trained to operate new equipment. Regularly review performance metrics to identify areas for further efficiency gains, as continuous improvement is key in the evolving landscape of industrial packaging.

Top Manufacturers and Brands of Packaging Equipment

When selecting industrial packaging equipment for your business, it is essential to consider the top manufacturers and brands that lead the market. According to industry reports, the global packaging equipment market is projected to grow to $50 billion by 2027, driven by advancements in technology and an increasing demand for efficient packaging solutions. This growth speaks to the importance of choosing equipment from reputable manufacturers who can provide both reliability and innovation.

Key manufacturers in the packaging industry are focusing on sustainable practices and automation to meet the rising demands of various sectors, including food and beverage, pharmaceuticals, and consumer goods. Surveys indicate that over 60% of companies prioritize sustainability in their purchasing decisions, highlighting the need for equipment that incorporates eco-friendly practices. Additionally, the trend towards automation is significant, with investments in packaging automation systems expected to reach $27 billion by 2025. This shift not only improves efficiency but also enhances the overall production process, reducing labor costs and minimizing human error.

By aligning with established brands that emphasize these trends, businesses can ensure they are equipped with the latest technology and sustainable solutions. The selection of robust packaging equipment from these top manufacturers will ultimately lead to increased productivity and competitiveness in the ever-evolving market landscape.

Future Trends in Industrial Packaging Solutions

The landscape of industrial packaging solutions is rapidly evolving, influenced by advancements in technology and growing environmental concerns. One of the most significant trends is the integration of automation. Automated packaging systems streamline operations, boost productivity, and reduce labor costs. Businesses adopting these solutions can not only keep pace with increased demand but also enhance precision and consistency in their packaging processes.

Tips: When considering automation, evaluate the scalability of the equipment based on your production needs. This ensures that your investment remains relevant as your business grows.

Another emerging trend is the shift towards sustainable packaging materials. Companies are increasingly seeking biodegradable and recyclable options to reduce their environmental footprint. Innovative materials, such as plant-based plastics, are being developed to replace traditional packaging, aligning with global sustainability goals. This shift not only meets consumer demand for eco-friendly practices but can also lead to long-term cost savings.

Tips: Conduct thorough research on the lifecycle of the materials you choose. Opt for suppliers who prioritize sustainability to enhance your brand’s reputation in the market.

Top 10 Industrial Packaging Equipment You Must Consider for Your Business - Future Trends in Industrial Packaging Solutions

| Equipment Type | Key Features | Typical Applications | Future Trends |

|---|---|---|---|

| Automated Stretch Wrappers | High speed, film saving, multi-size | Palletized products | Integration with IoT for monitoring |

| Case Sealers | Automatic adjustment, low maintenance | Box sealing for various sizes | Use of robotics for customization |

| Labeling Machines | High accuracy, quick changeovers | Food, beverage, cosmetics | Smart labeling with data tracking |

| Filling Machines | Versatile, sanitary, easy cleanup | Liquids, powders, granules | Robotics for precision filling |

| Shrink Wrappers | Compact design, energy-efficient | Bundling products | Enhanced shrink films and eco-options |

| Conveyor Systems | Modular, durable, high-speed | Assembly lines, packaging stations | Smart technology integration |

| Stretch Film Dispensers | Easy handling, adjustable tension | Pallet wrapping | Automation for increased efficiency |

| Palletizers | Robotic arms, flexible setups | High-volume production | AI for optimized stacking patterns |

| Dust Covers | Custom-fit, durable materials | Product protection | Sustainable materials usage |

| Inspection Systems | Vision systems, error detection | Quality control | Integration with machine learning |

Related Posts

-

Top 10 Industrial Packaging Equipment Solutions for Efficient Operations

-

How to Choose the Right Industrial Packaging Equipment for Your Business

-

How to Implement Food Packaging Automation for Maximum Efficiency and Cost Savings

-

Why Choosing the Right Packaging Solutions is Crucial for Your Business Success

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss