The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What is Packing Equipment and How to Choose the Right One for Your Needs

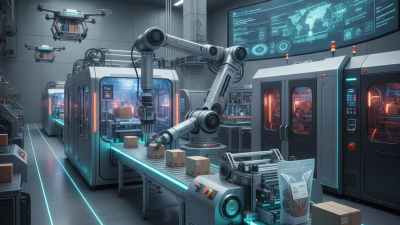

In today's fast-paced industrial landscape, the significance of packing equipment cannot be overstated. It plays a crucial role in ensuring that products are securely packaged, preserving quality and minimizing waste. According to a report by Grand View Research, the global packaging equipment market size was valued at approximately $45 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of around 5.6% from 2023 to 2030. This growth highlights the increasing demand for efficient and reliable packing solutions across various industries.

Choosing the right packing equipment can be a daunting task, as it requires a thorough understanding of specific needs and operational capabilities. “The correct packing equipment not only enhances productivity but also significantly reduces costs in the long run,” says John Smith, a leading expert in packaging technology. His insights emphasize the importance of assessing factors such as product size, type of packaging material, and production volume before making a decision.

As businesses strive for greater efficiency, selecting the appropriate packing equipment becomes an integral aspect of their operational strategies. Understanding the nuances of different technologies and solutions available in the market is essential for optimizing production processes while meeting customer expectations. In this guide, we'll explore the various types of packing equipment and provide insights to help you make informed decisions tailored to your specific requirements.

Understanding the Basics of Packing Equipment and Its Functions

Packing equipment plays a crucial role in various industries by ensuring that products are securely packaged for storage, transport, and sale. Understanding the basics of packing equipment involves familiarizing oneself with different types, such as sealers, fillers, and wrappers. Each type serves a specific function, contributing to the overall efficiency of the packing process. For instance, sealers are used to protect products from moisture and contamination, while fillers ensure that packages are filled consistently and appropriately.

When selecting packing equipment, it's essential to consider the nature of the products being packed. Factors such as size, weight, and material compatibility can determine which equipment is best suited for the job. Additionally, the volume of items needing packaging can influence your choice, whether you require high-speed machines for large quantities or more manual options for smaller operations.

Tips: Always assess the total cost of ownership for packing equipment, which includes maintenance, operational costs, and efficiency. Investing in quality equipment may lead to greater long-term savings. Additionally, don't overlook user-friendliness—equipment that is easy to operate will reduce training times and minimize errors during the packing process.

Types of Packing Equipment: An Overview of Your Options

When selecting packing equipment, understanding the various types available is essential for optimizing your shipping and storage processes. One common type is the manual packing station, which is ideal for smaller operations. These setups typically include tables, tape dispensers, and cushioning materials, allowing workers to package items efficiently without needing automated systems. Manual packing stations are flexible and can be easily customized to fit different product sizes and packing requirements.

On the other hand, businesses with higher volume needs might consider automated packing equipment. This includes machines that can wrap, box, or seal products more quickly and consistently than manual methods. Automated systems can range from simple semi-automatic machines to fully integrated robotic packing lines, enabling greater throughput and reducing labor costs. Additionally, specialized equipment like vacuum sealers or shrink wrappers can enhance product protection and shelf life, particularly for perishable goods.

Lastly, it is important to assess packaging materials when choosing packing equipment. Different materials, such as cardboard, plastic, or biodegradable options, can influence the type of equipment needed. For instance, a company focused on sustainability may prioritize equipment that accommodates eco-friendly packaging. Evaluating your packing needs based on product characteristics, order volume, and sustainability goals will guide you in selecting the right packing equipment to enhance efficiency and effectiveness.

Key Factors to Consider When Choosing Packing Equipment

When selecting packing equipment, several key factors should be at the forefront of your decision-making process. First and foremost, assess the nature of the products you are packaging. Different items require different types of packing solutions; for example, fragile items may need cushioning packaging, while bulkier items might necessitate sturdy crates or pallets. Moreover, consider the size and weight of your products, as this will directly influence the type of equipment required for efficient packing and transport.

Another crucial aspect to evaluate is the speed and efficiency of the packing process. Depending on your production demands, you may need equipment that can handle high volumes of goods quickly, which may entail automated systems. Additionally, think about the ease of use and maintenance of the equipment; user-friendly designs and minimal maintenance requirements can save both time and resources in the long run. Finally, consider your budget and the potential return on investment. While an initial higher cost might seem daunting, efficiency and durability in the long term can lead to significant savings.

Evaluating Your Business Needs for Packing Solutions

When evaluating your business needs for packing solutions, the first step is to assess the types of products you handle. Consider the size, shape, and fragility of your items, as these factors will dictate the most appropriate packing equipment. For instance, irregularly shaped products may require custom packaging solutions, while fragile items will need cushioning features to prevent damage during transit. This assessment will also involve understanding the volume of products you ship regularly, as high-volume operations may benefit from automated systems to improve efficiency.

Next, it's essential to think about your operational workflow and space constraints. Analyze how packing integrates with your distribution process. If space is limited, compact packing machines that can efficiently utilize vertical space may be ideal. Additionally, consider the ease of use and training required for your staff. Selecting equipment that is user-friendly will help minimize downtime and enhance productivity. By aligning your packing equipment choices with your specific business needs, you can optimize your packing process, reduce costs, and improve overall customer satisfaction.

Best Practices for Maintaining Packing Equipment Efficiency

Maintaining the efficiency of packing equipment is crucial for optimizing operational workflows and reducing downtime. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), up to 30% of a facility’s total production time can be lost due to equipment inefficiencies. Regular maintenance practices, such as scheduled inspections and prompt repairs, can help mitigate these losses and prolong the life of packing machinery. It’s essential to establish a maintenance schedule based on the manufacturer's guidelines and the unique demands of the production environment.

One effective strategy for enhancing packing equipment efficiency is to invest in training for operators. A study from the International Society of Automation revealed that facilities with trained personnel saw a 20% increase in machine performance. Training should cover not only the operational aspects but also troubleshooting techniques, as this empowers employees to handle minor issues before they escalate, ensuring smoother operations. Moreover, implementing technology such as predictive maintenance analytics can significantly reduce unplanned downtime. Utilizing sensors and data analytics to monitor equipment performance can lead to proactive maintenance strategies, optimizing both efficiency and overall productivity.

Related Posts

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management

-

2025 Top 10 Packer Machines Revolutionizing Packaging Efficiency with 20 Percent Faster Processing

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry

-

2025 How to Choose the Best Packer Machine for Your Business Needs

-

How to Choose the Right Industrial Packaging Equipment for Your Business