The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What is Packaging Automation and How Will It Evolve by 2026?

Packaging automation refers to the technology used to automate the packaging process in various industries. This process significantly enhances efficiency and reduces labor costs. As businesses strive to meet growing consumer demands, packaging automation is becoming essential.

By 2026, we can expect further evolution in packaging automation technologies. Innovations like AI and robotics will transform traditional methods. This shift might lead to smarter systems that manage workflows better. However, not all companies will adapt seamlessly. Small businesses may face challenges in updates and investments.

The evolution of packaging automation reflects both progress and obstacles. While automated solutions promise efficiency, they also highlight potential job displacement. Companies must find a balance between technological advancements and workforce considerations. It's a complex journey, paving the way for a new packaging era.

What is Packaging Automation? An Overview of Its Definition and Applications

Packaging automation is the use of technology to streamline packaging processes. It encompasses various methods and machines that handle packaging tasks automatically. This increases efficiency and reduces errors. Businesses often adopt packaging automation to save time and costs. The technology can package products in a variety of materials, such as boxes, bags, or shrink wrap.

Applications of packaging automation are widespread. Industries like food, pharmaceuticals, and electronics utilize automated systems. These systems can fill containers, seal packages, and apply labels. However, some challenges arise. Not all products are suited for automation. Unique shapes and sizes may require specialized machines. This can lead to increased costs for smaller businesses.

As technology advances, packaging automation will evolve. Innovations like AI and robotics will enhance efficiency. However, there are concerns about job displacement. Still, automation can create new opportunities in tech-driven roles. The balance between efficiency and employment will be crucial. Companies should reflect on how to integrate automation responsibly.

What is Packaging Automation and How Will It Evolve by 2026?

| Dimension | 2023 Data | 2026 Projected Data |

|---|---|---|

| Market Size (USD Billion) | 20.3 | 40.5 |

| Adoption Rate (%) | 25% | 50% |

| Labor Cost Reduction (%) | 15% | 35% |

| Efficiency Improvement (%) | 20% | 40% |

| Sustainability Improvements (%) | 10% | 30% |

Current Trends in Packaging Automation: Market Growth and Technology Adoption

The packaging automation sector is experiencing significant growth. According to a recent market report, it is projected to reach a valuation of $75 billion by 2026. This growth is fueled by increased demand for efficient supply chains and enhanced product safety. Technology adoption plays a crucial role in this evolution. Companies are increasingly turning to robotics and artificial intelligence for automation tasks.

Factors driving this shift include labor shortages and a need for consistency. More businesses are investing in automated systems like case packing and palletizing. These systems reduce human error and improve production speed. Yet, companies face challenges in integrating these technologies effectively. Some struggle with costs, while others deal with a steep learning curve.

Tip: When considering automation, assess your specific needs. Not all solutions fit every situation.

Looking ahead, sustainability will shape the future of packaging automation. Brands will seek eco-friendly materials and processes. Efficiency isn't just about speed; it also involves minimizing waste. Adopting green technologies will likely become a priority.

Tip: Explore energy-efficient machines. They can cut long-term costs and environmental impact.

Ultimately, packaging automation represents a dynamic blend of opportunity and challenge. Companies should remain adaptable and open to continuous improvement.

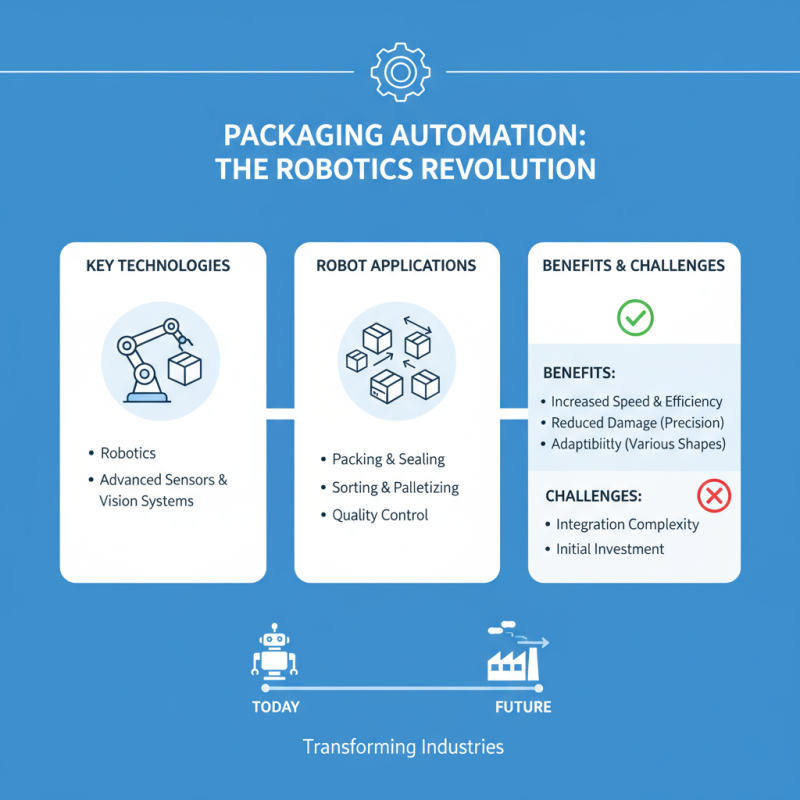

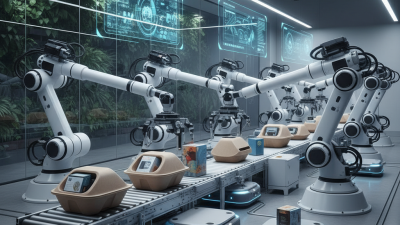

Key Technologies Driving Packaging Automation: Robotics, AI, and IoT

Packaging automation is transforming industries through advanced technologies. Robotics play a pivotal role in this shift. They aid in tasks such as packing, sorting, and palletizing. Robots are flexible and can adapt to different product shapes. Their precision reduces product damage, but this technology is not without challenges. For example, integrating robots into existing systems may require time and resources.

Artificial Intelligence (AI) enhances automation by analyzing data in real-time. AI can predict equipment failures, thereby minimizing downtime. However, relying on AI comes with risks. Algorithms may sometimes misinterpret data, leading to operational hiccups. Companies must regularly update their AI models to ensure accuracy.

The Internet of Things (IoT) connects machines in the packaging industry. Sensors track the entire process, improving efficiency. Yet, with greater connectivity, security concerns arise. Data breaches can disrupt operations and affect quality. Striking a balance between automation and security remains an ongoing challenge.

The Impact of Packaging Automation on Supply Chain Efficiency and Cost Reduction

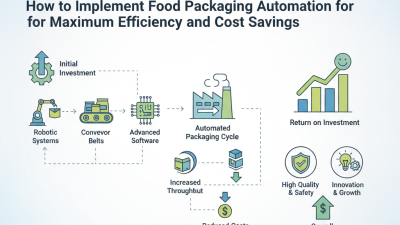

Packaging automation significantly enhances supply chain efficiency. By integrating automated systems, companies can reduce human error. It leads to faster processing times, which is critical in today’s fast-paced market. Automation accelerates packaging and reduces labor costs. Businesses can allocate these savings to other areas.

However, there are challenges. Investments in technology can be substantial. Companies must evaluate their return on investment carefully. Transitioning to automated processes can disrupt existing workflows. Staff training is crucial to ensure smooth operations. Without proper guidance, mistakes can happen.

**Tip:** Start small. Implement automation in one area before scaling up. This allows for manageable adjustments and minimizes disruption.

Another area to focus on is data integration. Automated systems must communicate effectively with inventory management. Poor integration can lead to bottlenecks. Companies should regularly review their processes to ensure systems work in harmony.

**Tip:** Schedule regular assessments. This helps identify potential issues before they escalate. Continuous improvement should be a priority.

Future Projections: How Packaging Automation Will Change by 2026

Packaging automation is on the brink of transformation by 2026. As industries adapt to consumer needs, the emphasis is shifting towards flexibility and efficiency. Automation technology is evolving rapidly, reducing human error and improving speed. Smart packaging will likely become more prevalent, integrating IoT devices to track products throughout the supply chain. This shift can enhance inventory management and reduce waste.

Tips: Consider shipping products with eco-friendly materials. This choice not only supports sustainability but also appeals to environmentally conscious consumers. Adopting new technologies is critical. However, careful implementation is key. New tools may require additional training for employees, which can lead to temporary productivity dips.

Automation can also present challenges. As machines take over repetitive tasks, the workforce must adapt. Workers may feel threatened by job changes or replacements. Businesses should reassure employees by emphasizing retraining programs. Engaging the workforce enables a smoother transition. Adapting to these changes is essential for all stakeholders involved.

Related Posts

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

How to Implement Food Packaging Automation for Maximum Efficiency and Cost Savings

-

What is Packing Equipment and How to Choose the Right One for Your Needs

-

2026 Best Automated Packaging Solutions for Your Business

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry