The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Choose the Right Packaging Equipment for Your Business Needs?

Choosing the right packaging equipment can seem daunting for many businesses. Industry expert Dr. Emily Parker emphasizes, "The right equipment can transform your production line." Her insights underline the significant impact packaging equipment has on efficiency and effectiveness.

Every business has unique needs. For a startup, the focus might be on cost-effectiveness. Established companies may seek advanced technology to improve output. Understanding these differences is crucial. Way too often, businesses choose equipment that doesn't align with their goals. This can lead to wasted resources and frustration.

Selecting suitable packaging equipment isn't merely a matter of price. It's about matching features to demands. Consider the product type, volume, and shelf life. Sometimes, a less popular option might serve you better. Reflecting on these factors can prevent costly mistakes and streamline operations.

Understanding Your Packaging Requirements and Objectives

Understanding your packaging requirements is crucial for any business. Assess the nature of your products. Consider their size, weight, and fragility. Are they perishable? Do they need special protection? These questions guide your choices. For example, fragile items may require cushioning materials. Heavy products might need robust boxes.

Next, think about your objectives. Are you focusing on minimizing costs or enhancing aesthetics? Balancing cost and quality can be challenging. Sometimes, cheaper options lead to higher expenses later. Consider how packaging impacts brand perception. A well-designed package attracts customers. However, if you overlook durability, it can backfire.

Reflect on your target market as well. Their preferences can dictate packaging styles. Eco-friendly options are becoming popular. Some customers prioritize sustainability over price. This shift can influence your choices significantly. But will all customers appreciate this choice? It's worth testing different approaches to find the right mix.

Assessing Different Types of Packaging Equipment Available

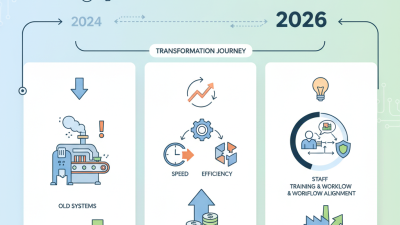

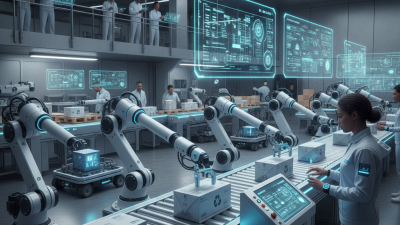

When selecting packaging equipment, businesses face a variety of options. Understanding these choices is crucial. According to a recent industry report, the global packaging equipment market is projected to reach $50 billion by 2026, reflecting a growing demand for efficient solutions. Companies are increasingly turning to automated machinery, including case packers and palletizers, to enhance their operations. Automated systems can improve speed and accuracy, reducing labor costs by up to 20%.

Different types of packaging machines cater to various needs. For instance, vertical form-fill-seal machines are popular in the food industry. They offer high-speed packaging for products like snacks and frozen foods. Another option is shrink wrapping machines, favored for their ability to protect products during transport. However, choosing the right machine involves assessing your specific requirements. Factors such as production volume, product type, and budget constraints must be considered.

It's important to reflect on your long-term goals. The wrong choice can lead to inefficiencies. Evaluating the scalability of equipment is essential. As your business grows, will your equipment adapt? Understanding the flexibility of your packaging solutions can save time and money down the road. Proper research and foresight into the available options will be key to making the best decision for your business needs.

Factors to Consider When Choosing Packaging Equipment

Choosing the right packaging equipment can be daunting. One key factor is the nature of your product. Different items require different types of packaging. For instance, fragile items need cushioning. Heavier products may need sturdier materials. You must assess the specifics of your products carefully.

Additionally, consider production volume. High-volume operations might need faster, more automated solutions. However, if your production is small-scale, flexibility could be more valuable. Sometimes, a simple manual approach works best. Cost is always a factor. Explore budget-friendly options. But beware, cheaper doesn't always mean better. Investing in quality equipment may save you money long term.

Don't overlook the environmental impact of your packaging choices. Sustainable options are increasingly important. Customers value eco-friendly practices. Yet, transitioning to greener solutions can be challenging. It requires planning and testing to find the right balance. Reflect on what matters most for your brand.

How to Choose the Right Packaging Equipment for Your Business Needs?

| Factor | Description | Importance Level | Example Equipment |

|---|---|---|---|

| Product Type | What you are packaging (e.g., food, electronics) | High | Flow wrappers, shrink wrappers |

| Production Volume | The amount of product you need to package daily | High | Automated packaging lines |

| Space Availability | Space constraints in your facility | Medium | Compact packaging solutions |

| Budget | Financial resources allocated for equipment | High | Used packaging machines |

| Ease of Use | User-friendliness and training requirements | Medium | Semi-automatic machines |

| Maintenance Needs | Frequency and cost of servicing the machinery | High | Low-maintenance options |

| Regulatory Compliance | Requirements specific to your industry | High | FDA approved equipment for food packaging |

Evaluating Equipment Suppliers and Their Offerings

When selecting packaging equipment, evaluating suppliers is crucial. Look for those with experience in your industry. A reliable supplier understands specific requirements. They should also provide diverse solutions. This flexibility can benefit your unique operations.

Assess their product range carefully. Do they offer machinery that suits various packaging types? A single solution may not fit all needs. Inquire about customization options, too. Some suppliers might struggle to cater to specific demands, which could leave your business vulnerable.

It's also essential to consider after-sales support. Will they assist with installation and training? A good supplier provides ongoing maintenance options. This partnership can ensure equipment longevity. However, not every supplier can deliver consistent service. Prioritize those who can show a track record of reliability. Experience matters, but so does adaptability in today’s dynamic markets.

Ensuring Compatibility with Existing Production Processes

When selecting packaging equipment, compatibility with your existing production processes is crucial. Examine your current workflow. Identify any bottlenecks or inefficiencies. Mapping out these aspects helps you find equipment that enhances your productivity. For instance, if your line processes liquids, the equipment must efficiently integrate with filling machines. Inadequate compatibility can lead to wasted time.

Consider the size and capacity needs. If your business expands, the equipment should scale accordingly. Equipment that cannot adapt may not provide the return on investment you expect. Pay attention to features that align with your existing machinery. Adjustments can be costly. Also, assess the learning curve for your team. Equipment that’s difficult to operate can lead to errors. Mistakes can diminish productivity and impact quality.

Always prioritize maintenance and support options. Equipment with limited service availability can become a headache during breakdowns. Training for staff is another consideration. Well-trained staff can operate equipment seamlessly, impacting output positively. Regular evaluations of your production process also help determine necessary changes. Look for areas where the new equipment can fill gaps or improve overall efficiency.

Related Posts

-

What is Packing Equipment and How to Choose the Right One for Your Needs

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

How to Choose the Right Industrial Packaging Equipment for Your Business

-

Top 10 Industrial Packaging Equipment Solutions for Efficient Operations

-

2026 Best Packaging Equipment Systems for Efficient Production?

-

What is Packaging Automation and How Will It Evolve by 2026?