The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Choose the Right Automated Packaging Equipment for Your Business?

Automated packaging equipment is revolutionizing the manufacturing landscape. According to a recent study, companies using this technology can increase efficiency by up to 30%. These machines reduce labor costs and improve consistency in product quality. Choosing the right equipment can be a daunting task, given the myriad of options available.

Factors such as production volume and product type must be considered. For instance, a small business might not need high-speed packaging solutions. They could over-invest in technology that isn't necessary. On the other hand, larger businesses may struggle to keep up with demand without automation. A recent report indicates that nearly 70% of global manufacturers plan to implement or upgrade their automated packaging systems in the next five years.

The challenge lies in selecting equipment tailored to specific needs. Inaccurate choices can lead to workflow disruptions and financial strain. Understanding industry needs is crucial. Ultimately, the goal is to enhance packaging efficiency while managing costs effectively. Automated packaging equipment has the potential to transform processes when aligned with business objectives.

Identifying Your Packaging Needs and Business Goals

When choosing automated packaging equipment, identifying your packaging needs and business goals is crucial. Start with understanding your product specifications. Consider size, fragility, and compliance requirements. According to a recent industry report, 70% of businesses experience delays due to inadequate packaging processes. This means assessing your current workflow can reveal areas for improvement.

Next, evaluate your production volume. High-demand products might require faster packaging solutions. The same report indicates that companies using automated equipment saw a 40% increase in efficiency. However, not every operation needs high-capacity machinery. Sometimes, lesser automation can provide flexibility without overspending. Balancing speed and adaptability is key.

Lastly, think about your budget and return on investment. Investing in advanced technology might seem appealing, but it’s essential to analyze the long-term benefits. Some companies reported overestimating their needs and purchasing oversized machines. It’s important to align equipment capabilities with actual business objectives. Reflect on what will truly support your growth in the long run.

Automated Packaging Equipment: Key Features vs. Business Goals

Evaluating Different Types of Automated Packaging Equipment

Evaluating different types of automated packaging equipment is crucial for optimizing production. The market offers various options, including case sealers, filling machines, and shrink wrappers. Each type serves specific needs. For instance, case sealers are ideal for high-speed operations, while filling machines focus on precise volume control. According to industry reports, about 40% of companies experienced increased efficiency after switching to automated systems.

Moreover, understanding your product's characteristics is essential. Fragile items may require cushioning mechanisms, while liquids need specialized filling. It's reported that over 30% of packaging failures stem from inadequate equipment selection. This highlights the need for careful evaluation. Some businesses might overlook maintenance schedules, leading to unplanned downtimes. Regular assessments are necessary to prevent operational interruptions.

Price is another significant factor. While the initial investment may be high, the long-term savings can be substantial. Studies show that automated systems can reduce labor costs by up to 25%. However, businesses must weigh costs against their specific packaging challenges and goals. Choosing the right equipment requires a balance of efficiency, cost-effectiveness, and product requirements.

Understanding the Cost vs. Benefit Analysis for Packaging Solutions

When considering automated packaging equipment, the cost versus benefit analysis is crucial. A meticulous evaluation helps identify profitability. Initial investment costs can seem high, but long-term savings often make up for it. For instance, an automated line may reduce labor costs significantly. Think about how many hours your staff would save.

However, not every business needs the latest technology. Some may find that existing methods work well enough. This is worth contemplating. Assess your production volume. A smaller operation might not see enough gain from automation to justify the expense. Maintenance costs can also add up. Be prepared for unexpected repairs.

Moreover, consider the flexibility of the equipment. Can it handle different package sizes? If your product line changes frequently, this is a vital aspect. You may face additional costs for modifications. Engaging with your team during this decision is important. Their insights into daily operations can reveal untapped potential. It’s a balancing act that requires careful thought and planning.

How to Choose the Right Automated Packaging Equipment for Your Business? - Understanding the Cost vs. Benefit Analysis for Packaging Solutions

| Packaging Equipment Type | Initial Cost ($) | Annual Maintenance Cost ($) | Production Speed (units/hour) | Labor Savings (%) | Return on Investment (%) |

|---|---|---|---|---|---|

| Automatic Cartoning Machine | 50,000 | 3,000 | 120 | 20 | 150 |

| Robotic Palletizer | 75,000 | 5,000 | 200 | 30 | 200 |

| Shrink Wrapping Machine | 40,000 | 2,500 | 150 | 15 | 120 |

| Fill-Seal Machine | 60,000 | 4,000 | 180 | 25 | 180 |

| Labeling Machine | 20,000 | 1,500 | 300 | 10 | 110 |

Assessing Space and Workflow Considerations for Equipment Placement

When choosing automated packaging equipment, space and workflow considerations are vital. Many facilities underestimate how much space they need for machinery. According to a recent industry report, about 30% of businesses experience inefficiencies due to improper layout. If equipment is cramped, it hampers productivity and slows down operations.

Before making a purchase, analyze the physical space in your facility. Measure the area where the equipment will reside. Allow for both machinery size and necessary working space. Ideal workflow includes room for employees to move freely. Limited space could lead to accidents or slowdowns.

You might also consider equipment configuration. A linear setup might work well for certain products. However, for diverse lines, a modular approach could be beneficial. An organization’s workflow may shift, requiring adaptations in equipment placement over time. Regular reviews of your layout can prevent bottlenecks. Research suggests that optimized workflows can improve efficiency by up to 25%.

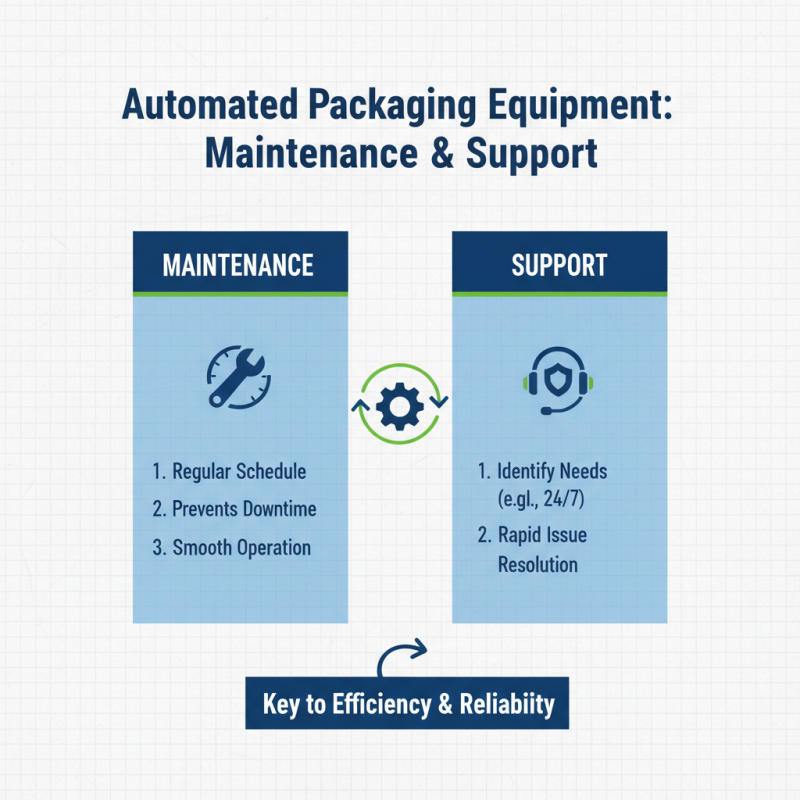

Exploring Maintenance and Support Options for Automated Machinery

When investing in automated packaging equipment, maintenance and support options play a crucial role. Regular maintenance ensures the machinery runs smoothly and efficiently, minimizing downtime. Have a clear maintenance schedule in place. This helps prevent unexpected breakdowns that can disrupt your operations. Identify what level of support your business requires. Will you need 24/7 assistance, or is standard support sufficient?

Additionally, consider the training for your staff. Ideally, operators should be well-versed in routine checks and basic troubleshooting. Sometimes, operations might slow down because employees are unsure about machine features. Invest time in comprehensive training sessions. This can significantly improve overall productivity and equipment lifespan.

Don’t overlook the importance of spare parts availability. Sometimes, parts may not be in stock when you need them the most. This can hinder operations and affect customer satisfaction. Ensuring a reliable supply chain for parts is vital. Reflect on these aspects regularly. Your criteria for support may shift as your business evolves.

Related Posts

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry

-

How to Choose the Right Industrial Packaging Equipment for Your Business

-

Top 10 Industrial Food Packaging Machines for Your Production Line

-

2026 Best Automated Packaging Solutions for Your Business

-

2026 Best Packaging Equipment Systems for Efficient Production?

-

Top 10 Benefits of Using a Case Packer Machine in Your Packaging Line