The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Choose the Right Case Packer Machine for Your Business Needs

When it comes to optimizing your packaging process, selecting the right case packer machine is crucial for ensuring efficiency and productivity. According to industry expert John Smith, a leading figure in packaging solutions, "The right case packer machine can significantly enhance your operation's speed and reduce labor costs." This assertion underscores the importance of carefully evaluating various options available in the market to find a machine that meets your specific business requirements.

Understanding the unique demands of your production line—such as product type, packaging size, and throughput needs—can help in determining which case packer machine is best suited for your operations. As businesses grow and evolve, the need for an adaptable and reliable case packing solution becomes increasingly vital. With advancements in technology, case packer machines have become more sophisticated, offering features that cater to diverse applications and industries.

In this guide, we will explore the key factors to consider when selecting a case packer machine, ensuring that your investment contributes positively to your overall efficiency and aligns with your long-term goals. By making informed decisions, you can streamline your packaging processes, enhance product safety, and ultimately improve your bottom line.

Understanding the Role of Case Packer Machines in Packaging Operations

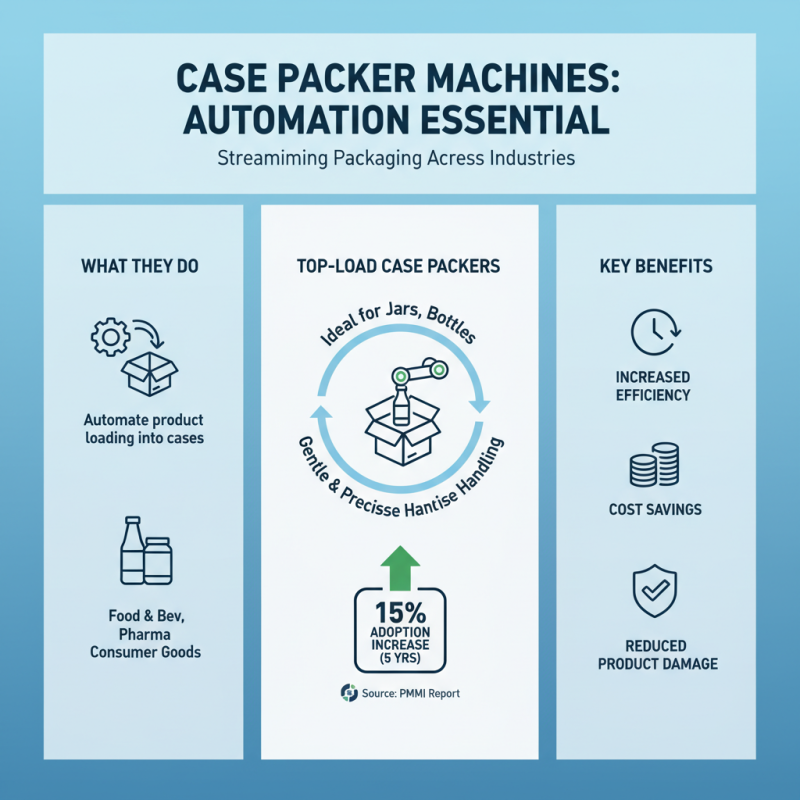

Case packer machines play a vital role in modern packaging operations, serving as a crucial link in the supply chain for numerous industries, including food and beverage, pharmaceuticals, and consumer goods. According to the Packaging Machinery Manufacturers Institute, the demand for case packing solutions is projected to grow by approximately 4.5% annually through 2026, driven by the increasing need for efficiency and productivity in packaging processes. These machines automate the packaging of products into cases, facilitating quicker turnaround times and reducing labor costs.

Moreover, case packer machines enhance the overall efficiency of packaging lines by minimizing human error and ensuring consistent product placement. A study by PMMI Business Intelligence highlights that nearly 55% of companies report significant improvements in their packaging efficiency after incorporating automated case packing solutions. This automation also provides companies with the flexibility to adapt to varying production volumes and packaging formats, ultimately leading to increased competitiveness in a rapidly evolving market. As businesses continue to strive for operational excellence, understanding the role and benefits of case packer machines becomes essential for selecting the right equipment tailored to specific operational needs.

Identifying Your Business Requirements for a Case Packer Machine

When selecting a case packer machine, the first step is to identify your specific business requirements. This involves understanding the nature of your products, the packaging materials you use, and your production volume. For instance, if you handle fragile items, a machine with gentle handling capabilities may be essential to avoid damage during the packing process. Additionally, if your products vary in size or shape, consider a versatile case packer that can accommodate diverse packaging formats.

Another critical consideration is the throughput rate that aligns with your production goals. Analyze your current operational capacity and any anticipated growth to ensure that the case packer can meet both current and future demands. It’s also important to assess the machine's compatibility with existing production lines and workflows. An efficient case packer should integrate seamlessly into your operations, minimizing downtime and maximizing productivity. Ultimately, prioritizing these requirements will help you select a machine that enhances efficiency and meets your business's long-term objectives.

Key Features to Consider When Selecting a Case Packer Machine

When selecting a case packer machine for your business needs, it is essential to consider several key features that will affect both efficiency and productivity. First and foremost, assess the machine's speed and capacity. Depending on your production volume, you will want a case packer that matches your output requirements, whether you are packing small batches or large quantities. Understanding the machine's speed in terms of cases per minute can help you determine if it aligns with your production goals.

Another critical feature is the versatility of the machine. Look for a case packer that can accommodate various box styles and sizes, allowing for flexibility as your packaging needs evolve. Additionally, consider the automation level; semi-automatic machines might be sufficient for smaller operations, while fully automatic options are typically more suitable for high-volume production lines. Finally, evaluate the machine's ease of maintenance and operation. A user-friendly interface and accessible maintenance points can significantly reduce downtime and operational costs, ensuring a smoother workflow within your production environment.

How to Choose the Right Case Packer Machine for Your Business Needs - Key Features to Consider When Selecting a Case Packer Machine

| Feature | Description | Importance |

|---|---|---|

| Speed | The number of cases packed per minute. | High |

| Flexibility | Ability to handle different case sizes and styles. | Medium |

| Ease of Use | User-friendly interface and easy setup. | High |

| Durability | Ability to withstand continuous operation. | High |

| Maintenance | Frequency and ease of maintenance required. | Medium |

| Cost | Initial purchase price and total cost of ownership. | High |

| Automation Level | Degree of automated processes involved. | High |

| Safety Features | Incorporation of safety mechanisms to protect operators. | High |

Types of Case Packer Machines and Their Suitable Applications

Case packer machines are essential for automating the packaging process in a variety of industries, including food and beverage, pharmaceuticals, and consumer goods. These machines come in several types, each designed for specific applications. For instance, top-load case packers are ideal for products such as jars and bottles, which require gentle handling and precise placement into cases. According to a recent industry report by PMMI, the Association for Packaging and Processing Technologies, top-load case packers have seen a 15% increase in adoption rates over the past five years, reflecting their growing popularity in high-speed production environments.

On the other hand, tray packers are more suited for items that require stable packaging, such as canned goods or boxed products. These machines create a tray-like structure that offers superior stability during shipping and storage. Industry statistics indicate that tray packers hold approximately 30% of the case packing machinery market, largely due to their efficiency and ability to handle a wide range of product shapes and sizes. Furthermore, robotic case packers are gaining traction, particularly for businesses looking to enhance flexibility and reduce labor costs. They can adapt quickly to different packaging specifications, making them a preferred choice in facilities with diverse products. As processing technology continues to evolve, selecting the right case packer machine is crucial for optimizing productivity and ensuring packaging integrity.

Evaluating Cost and Return on Investment for Case Packer Machines

When evaluating the cost and return on investment (ROI) for case packer machines, it is crucial to consider both the initial expenditure and long-term savings they can provide. A detailed report by the Packaging Machinery Manufacturers Institute indicates that automating case packing can reduce labor costs by 30-50%, significantly impacting a company's bottom line. Given that average labor costs in manufacturing continue to rise, investing in a case packer is often financially prudent.

Additionally, productivity gains from implementing a case packer machine are notable. According to a study by PMMI, companies that adopted automated packaging solutions reported production increases between 20-40%. This boost not only reduces the time spent on packing but also minimizes human error, which can lead to costly mistakes. Ultimately, assessing the ROI should involve a holistic approach that factors in not only the monetary outlay but also the increase in efficiency and reliability these machines offer, making them a worthwhile consideration for businesses seeking to enhance their packaging operations.

Cost and Return on Investment for Case Packer Machines

Related Posts

-

What is a Case Packer and How Does it Work in Packaging Automation

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management

-

2025 Top 10 Packer Machines Revolutionizing Packaging Efficiency with 20 Percent Faster Processing

-

2025 Top 10 Packaging Systems Innovations to Boost Your Business Efficiency

-

How to Choose the Right Industrial Packaging Equipment for Your Business

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss