The Duravant family of operating companies serve the food processing, packaging and material handling segments.

2026 Best Packaging Equipment Systems for Efficient Production?

In the dynamic world of manufacturing, the role of packaging equipment systems is pivotal. As companies seek efficiency, understanding the latest advancements is crucial. Industry expert John Thompson highlights, "Innovative packaging equipment can transform production lines beyond expectations." His insight underscores the urgency for businesses to adapt to evolving technologies.

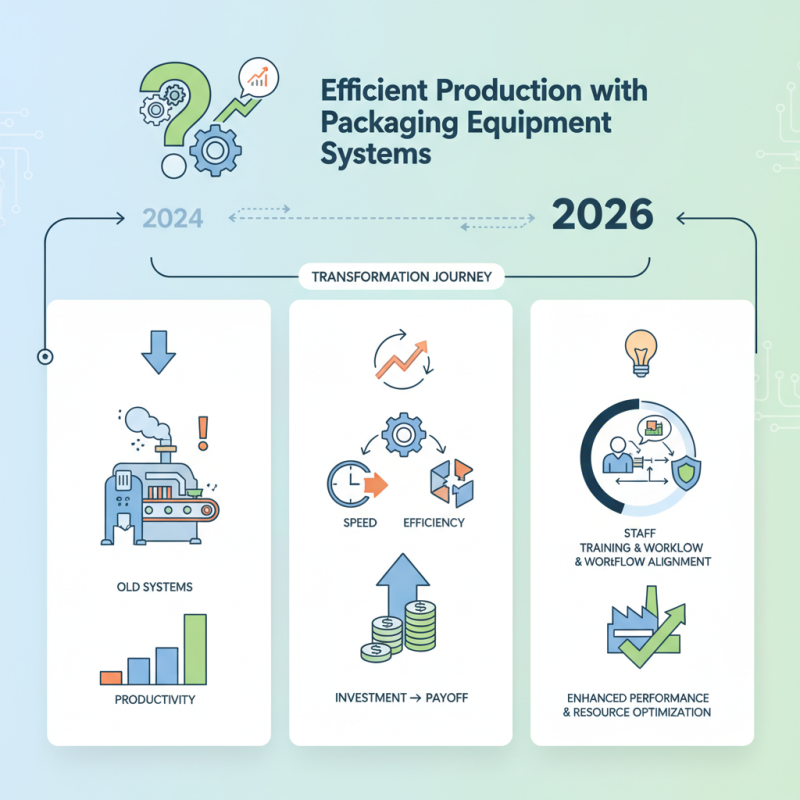

In 2026, the best packaging equipment systems will likely showcase efficiency, speed, and flexibility. Companies must evaluate their current systems. Many still rely on outdated machinery, which can hinder productivity. Yet, the investment in modern systems can pay off significantly. However, not every system will suit every production line. Businesses need to assess their specific needs carefully.

Embracing change is not always easy. Companies should also consider potential challenges in integrating new systems. Training staff and aligning workflows may require time and effort. Despite these hurdles, the benefits of advanced packaging equipment systems cannot be ignored. They promise enhanced performance and better use of resources for future production demands.

Overview of Packaging Equipment Systems in 2026

In 2026, the landscape of packaging equipment systems is evolving rapidly. According to recent industry reports, the market is projected to reach $50 billion, driven by the surge in e-commerce and consumer demand for sustainability. Automation is becoming a necessity, with 75% of companies investing in smart packaging technology to boost efficiency. This shift highlights the need for adaptation.

However, the transition to these advanced systems is not without challenges. Many manufacturers struggle with integrating new technologies into existing workflows. Approximately 40% of companies report difficulties in training staff on advanced machinery. This gap can lead to inefficiencies and increased downtime. Moreover, while automation improves speed, it may sometimes compromise flexibility, making it hard to switch between different products.

Sustainability is also a critical focus. Reports suggest that 60% of consumers prefer eco-friendly packaging. In response, businesses are exploring innovative materials and processes. Yet, many organizations are still grappling with high costs associated with sustainable technologies. This struggle complicates their path towards efficient production. The balance between cost, efficiency, and sustainability remains a significant challenge in 2026.

2026 Best Packaging Equipment Systems for Efficient Production

| System Type | Max Throughput (units/hour) | Efficiency (%) | Flexibility (1-10) | Typical Application |

|---|---|---|---|---|

| Automated Case Packaging | 1500 | 95 | 8 | Beverages and Bottled Goods |

| Vertical Form Fill Seal (VFFS) | 1200 | 90 | 9 | Snacks and Dry Foods |

| Labeling Systems | 1800 | 92 | 7 | Bottles and Cans |

| Shrink Wrapping Machines | 2000 | 93 | 6 | Multi-Pack Products |

| Tray Sealing Machines | 1000 | 94 | 7 | Fresh Foods and Ready Meals |

Trends Driving Efficiency in Modern Packaging Production

Efficiency in modern packaging production is influenced by various trends. Automation is at the forefront. It reduces human error and speeds up processes. Automated systems streamline tasks from filling to labeling. This can save significant time and labor costs. However, not every company can afford such technology. Smaller businesses may find it challenging to adopt these systems.

Sustainability is another driving force. Companies are shifting towards eco-friendly materials and processes. This change is often initiated by consumer demand. But, it is not always easy. Many firms grapple with finding the right sustainable materials that also meet safety standards. This is an ongoing challenge requiring innovation and investment.

Flexibility in production lines is becoming essential. Businesses need to adapt quickly to market demands. Packaging systems must be versatile enough to handle various product types. Yet, too much flexibility can complicate training and operational efficiency. Balancing adaptability with consistency remains a tough task for many manufacturers.

Key Technologies Enhancing Packaging System Performance

In the world of packaging, efficiency is key. Advanced technologies are transforming packaging systems. Automation is leading the way. Robotics optimize the packing process. They can handle various shapes and sizes with precision. This allows for faster production rates, reducing waste.

Smart sensors play a critical role too. These devices monitor the environment and product quality. They alert operators when issues arise. This immediate feedback prevents costly downtimes. However, integrating such technologies can be complex. Training staff to adapt is essential yet often overlooked.

Additionally, software solutions improve logistics. They streamline inventory management and reduce errors. An efficient system requires constant evaluation. It’s important to analyze performance data frequently. Finding areas for improvement can be challenging. Sometimes, companies get complacent. Continuous innovation is crucial for staying ahead in the game.

Evaluating Cost-Effectiveness of Packaging Equipment Investments

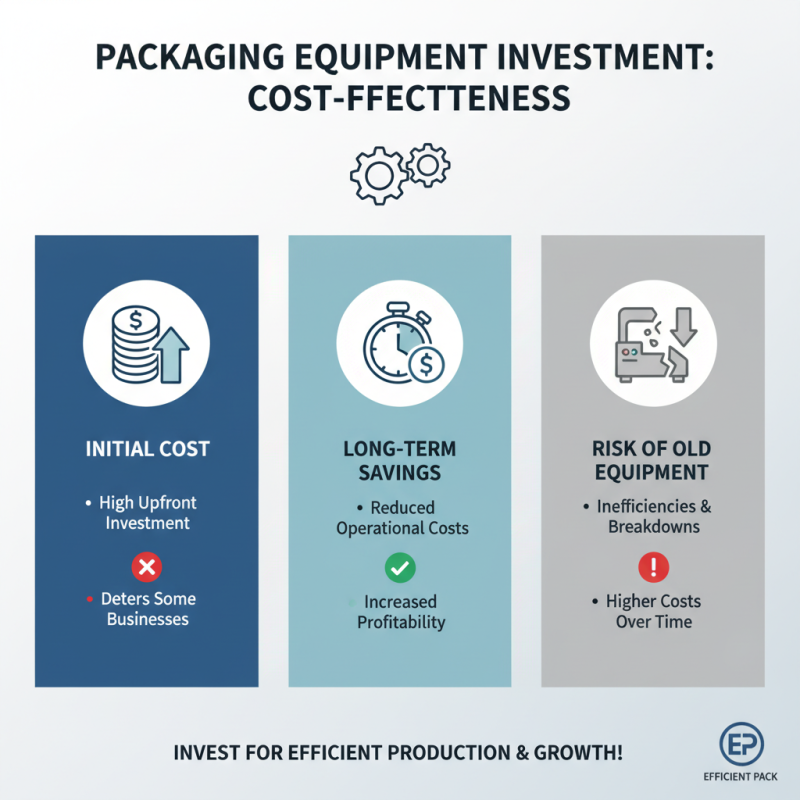

Investing in packaging equipment is crucial for businesses aiming for efficient production. However, evaluating cost-effectiveness can be challenging. Companies must consider initial costs versus long-term savings. A high upfront investment may deter some. Yet, outdated equipment can lead to inefficiencies and increased costs over time.

When selecting packaging equipment, here are a few tips. Analyze the equipment's lifespan. Short-lived machinery can lead to repeated expenses. Research the maintenance requirements. High maintenance can erode profit margins. Also, consider production volume. Ensure the equipment can handle current and future demands.

Additionally, engaging employees in the decision process is vital. Their insights may highlight overlooked factors. However, it's crucial to be aware of potential biases. Relying solely on personal familiarity with certain machines can cloud judgment. Keeping an open mind can lead to discovering better options. In the end, a balanced approach will yield the best outcomes.

Industry Case Studies: Success Stories of Efficient Packaging Solutions

In the dynamic world of packaging, efficiency is crucial. A recent industry report highlighted that companies investing in automated packaging systems can boost productivity by up to 30%. One notable case involved a food processing plant that revamped its packaging line, reducing labor costs significantly. They fully integrated new technology, yet faced hurdles with employee training and unforeseen machine downtimes.

Another case study emerged from the beverage sector. A company adopted a modular packaging approach, allowing for flexibility and fast adjustments. This led to a 25% reduction in package waste. However, they discovered the need for continuous monitoring of the system's performance. Despite achieving efficiency, they struggled with unexpected maintenance challenges that impacted production schedules.

These examples show that efficient packaging solutions require more than just technology. They need real-time adjustments and staff engagement. As companies recognize the potential gains, they must also confront the imperfections in implementation. Continuous improvement remains essential for long-term success in packaging systems.

Related Posts

-

How to Choose the Right Industrial Packaging Equipment for Your Business

-

Top 10 Industrial Packaging Equipment You Must Consider for Your Business

-

Top 10 Industrial Packaging Equipment Solutions for Efficient Operations

-

What is Packing Equipment and How to Choose the Right One for Your Needs

-

2025 Top 5 Food Bagging Machines You Need to Know About

-

How to Implement Food Packaging Automation for Maximum Efficiency and Cost Savings