The Duravant family of operating companies serve the food processing, packaging and material handling segments.

2026 Best Automated Packaging Solutions for Your Business

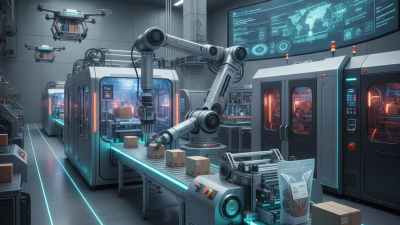

In today's fast-paced business landscape, the quest for efficiency drives many companies to explore automated packaging solutions. Industry expert Dr. Emily Carter states, “Automated packaging isn’t just a trend; it’s a necessity for growth.” This statement resonates deeply as businesses look to optimize their packaging processes. In 2026, the range of automated packaging solutions will be more vibrant than ever.

Diverse technologies will emerge, catering to various industries. For instance, faster machines, smarter software, and sustainable materials will shape the market. However, many companies still grapple with the transition to automated packaging. Challenges like initial investment and training remain significant hurdles. Companies must evaluate whether the benefits outweigh the costs.

Moreover, as potential users explore their options, they must consider not only efficiency but also flexibility and customization. The path to adopting automated packaging is filled with reflections. Asking tough questions and addressing imperfections in existing methods can pave the way for better solutions. In a world driven by speed and efficiency, embracing automation is essential yet complex.

Trends in Automated Packaging Solutions for 2026

In 2026, automated packaging solutions are evolving rapidly. Companies are focusing on sustainability and efficiency. New technologies aim to reduce waste and energy consumption. Innovative materials are emerging, allowing for lighter and stronger packaging. These improvements are essential as businesses strive to meet environmental goals.

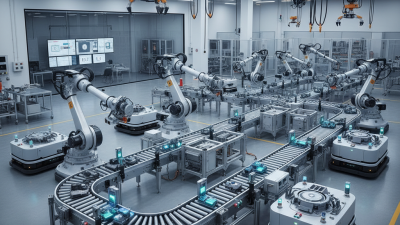

Robotics are central to this transformation. Automated systems now handle complex packaging tasks more efficiently. However, some challenges remain. Integration of these systems into existing workflows can be tricky. Employees may need retraining to adapt to new technologies. Companies must address this gap to maximize potential.

Data-driven solutions are also gaining traction. Businesses can analyze packaging processes in real-time. This allows for swift adjustments to improve performance. Yet, data privacy concerns arise. Companies must navigate these issues carefully. As the industry progresses, balancing innovation with ethical practices will be crucial.

2026 Best Automated Packaging Solutions for Your Business - Trends in Automated Packaging Solutions for 2026

| Solution Type | Key Features | Benefits | Expected Trends |

|---|---|---|---|

| Robotic Packaging | Versatile robotic arms, AI integration | Improved efficiency, reduced labor costs | Increased adoption in e-commerce |

| Automated Filling Machines | High-speed filling, adjustable nozzles | Enhanced productivity, consistent quality | Focus on sustainable materials |

| Labeling Solutions | Flexible labeling systems, high precision | Reduced errors, faster throughput | Integration with IoT |

| Case Packing Systems | Automated case erectors and packing | Lower operational costs, higher speed | Adaptation to smaller batch sizes |

| Robotic Palletizers | Advanced robotic systems for palletizing | Efficient space utilization, flexibility | Growth in urban logistics hubs |

Impact of Robotics and AI on Packaging Efficiency

The integration of robotics and AI in packaging processes is transforming the industry. Automated systems can handle various tasks, increasing efficiency and reducing human error. For instance, robotic arms can pack items faster than manual laborers. They are designed to work continuously, reducing downtime. This helps businesses meet production demands consistently.

However, relying solely on automation can lead to challenges. Machines need regular maintenance. Breakdowns can halt operations, causing delays. Moreover, not every packaging solution suits automation. Custom packaging still requires a human touch. The need for flexibility in design and packaging sometimes does not match robotic efficiency.

AI can analyze data to optimize packaging layouts. This minimizes waste and saves materials, which is crucial for sustainability. Yet, implementing these technologies requires investment. Not all businesses can afford the latest equipment. Balancing automation with human oversight often leads to the most effective results. As companies adapt, the journey toward full automation may require careful consideration and adjustment.

Key Statistics on Cost Savings through Automation in Packaging

Automated packaging solutions are gaining traction among businesses seeking efficiency. Recent statistics indicate that companies can save up to 30% on labor costs by implementing these technologies. This is a significant number, and it reflects a major shift towards automation. Many businesses are realizing that automated systems reduce errors and speed up production rates. However, the initial investment can be daunting.

In addition to labor savings, automation can enhance material usage. Optimized packaging reduces waste and decreases material costs significantly. Companies report a reduction in packaging waste by up to 20% after switching to automated solutions. While these numbers are promising, it's essential to consider the learning curve involved in adopting new technology. Employees might feel uncertain and require training to adapt to new systems.

Moreover, some organizations struggle with maintaining balance in their production lines. Overdependence on automation can lead to issues during downtime or maintenance. Implementing a blended approach may provide the flexibility needed to navigate these challenges. Achieving cost savings through automation requires careful planning and a willingness to adapt. Each company must assess its unique needs and capabilities before jumping in.

Sustainability Practices in Automated Packaging Systems

Sustainability is crucial in automated packaging solutions. These systems can minimize waste and reduce environmental impact. Using biodegradable materials is one way to promote eco-friendliness. Many businesses have started adopting these materials, but challenges remain.

Recycling is often overlooked in automated packaging. Some systems create a lot of waste, negating sustainability efforts. It's essential to design workflows that support recycling. Integrating returns into packaging systems can boost recyclability. Companies still need to evaluate their processes.

Energy efficiency is another aspect of sustainability. Automated systems that consume less electricity help lower carbon footprints. Not all machines are built equally. Some may use outdated technology that wastes energy. Investing in newer technology can be costly but may pay off in the long run.

Ultimately, sustainability in automated packaging is a work in progress. While many strides have been made, there is still much to learn and improve upon. Continuous evaluation and innovation are key to achieving true sustainability.

Top Automated Packaging Equipment for Different Industries in 2026

In 2026, businesses across various sectors seek efficient automated packaging solutions. The food and beverage industry leads the charge, driven by a demand for speed and safety. According to recent industry reports, companies focusing on automation can expect to enhance productivity by up to 30%. These systems reduce human error while increasing throughput.

In pharmaceuticals, automated packaging equipment has become essential. A report indicates that nearly 80% of pharmaceutical businesses are implementing automated processes to ensure compliance and accuracy. These solutions mitigate risks of contamination and damage. However, challenges remain, particularly in training staff to operate these sophisticated machines effectively.

The e-commerce sector continues to evolve rapidly, with customized packaging solutions gaining traction. Research indicates that over 60% of consumers prefer sustainable packaging options. Businesses may find integrating eco-friendly materials into automated systems challenging. Balancing efficiency and sustainability requires constant innovation. Ultimately, the right packaging solution aligns with both operational goals and consumer preferences.

Related Posts

-

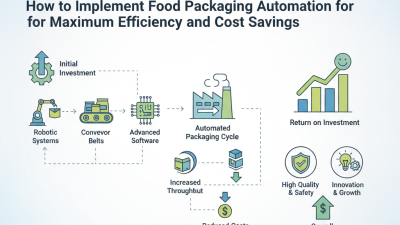

How to Implement Food Packaging Automation for Maximum Efficiency and Cost Savings

-

Top 10 Industrial Packaging Equipment Solutions for Efficient Operations

-

How to Implement Machinery Automation for Increased Efficiency and Productivity

-

Top 10 Benefits of Using a Case Packer Machine in Your Packaging Line

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss