The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Implement Machinery Automation for Increased Efficiency and Productivity

In today's fast-paced industrial environment, the pursuit of enhanced efficiency and productivity is more critical than ever. Companies are increasingly turning to machinery automation as a viable solution to streamline operations and maximize output. By automating repetitive and time-consuming tasks, businesses can reduce human error, lower operational costs, and allocate valuable resources to more strategic endeavors.

Machinery automation integrates advanced technologies and intelligent systems to create a seamless workflow, enabling organizations to respond rapidly to market demands. This not only leads to faster production cycles but also significantly improves product quality, fostering customer satisfaction and loyalty. As industries evolve and compete in a global marketplace, embracing machinery automation becomes not just an option but a necessity for those seeking to thrive.

In this article, we will explore various strategies for implementing machinery automation, addressing key considerations and best practices for achieving a successful transition. From assessing current operations to selecting the right technologies, we aim to provide insights that will empower businesses to harness the power of automation and unlock their full potential for growth and success.

Understanding Machinery Automation and Its Benefits

Machinery automation has become a critical component in enhancing operational efficiency and productivity across various industries. According to a report by McKinsey & Company, companies that implement advanced automation technologies can increase their productivity by up to 25% within a year. This substantial improvement is attributed to the reduced need for manual labor in repetitive tasks, enabling humans to focus on higher-value activities that require creative problem-solving and strategic planning.

The benefits of machinery automation extend beyond mere productivity gains. The World Economic Forum highlights that automating routine processes not only decreases labor costs but also significantly enhances precision and consistency. Automated machinery systems can operate 24/7 without fatigue, resulting in a dramatic reduction in production time, with some manufacturers reporting cycle time reductions of over 50%. Furthermore, the integration of smart technologies and machine learning in automation allows for real-time data analysis, improving decision-making and operational agility. Overall, embracing machinery automation presents an incredible opportunity for organizations to streamline their operations while achieving sustained growth and competitiveness in the marketplace.

Identifying Areas for Automation in Your Operations

Identifying areas for automation within your operations is a crucial first step toward enhancing efficiency and productivity. Start by conducting a thorough analysis of your current processes. Look for repetitive tasks that consume significant time and resources. These can often be streamlined or fully automated, allowing your team to focus on more value-adding activities. For instance, tasks like inventory management, data entry, and assembly line operations are common candidates for automation. Assess each process' output and frequency to determine the most suitable candidates for automation.

In addition to repetitive tasks, consider bottlenecks that slow down your workflow. These inefficiencies often lead to increased operational costs and delayed deliverables. Automation tools can help manage these bottlenecks by optimizing scheduling, workflow management, and resource allocation. Furthermore, involve your team in identifying pain points they encounter daily. Their insights can highlight areas where automation will have the most significant impact, enhancing overall morale and productivity as employees feel their challenges are being addressed. By focusing on specific areas for automation, businesses can implement targeted strategies to boost operational effectiveness.

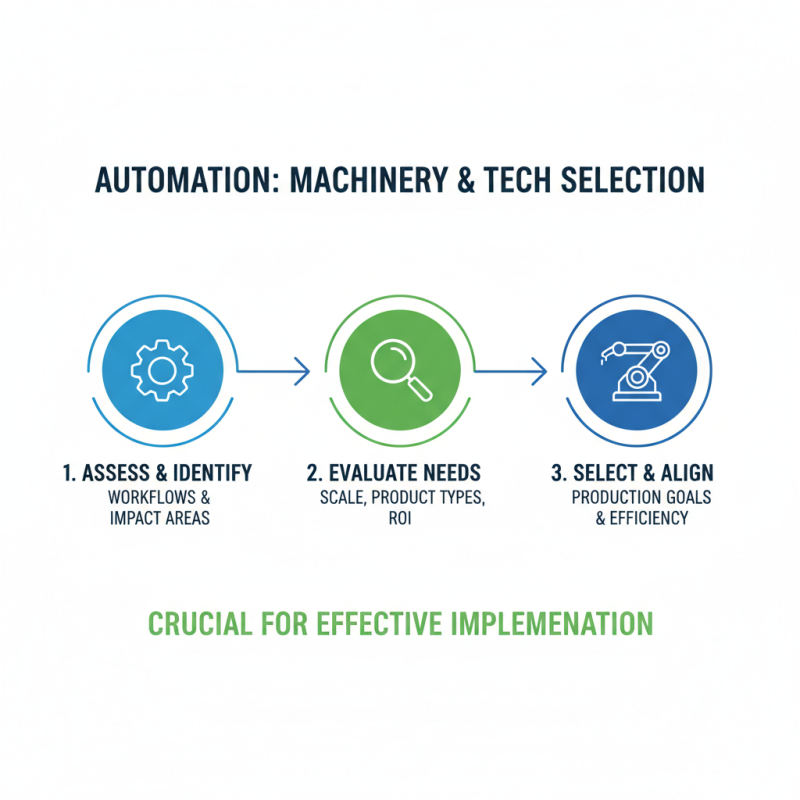

Selecting the Right Machinery and Technology Solutions

Selecting the right machinery and technology solutions is crucial for businesses seeking to implement automation effectively. The first step in this process involves conducting a thorough assessment of existing workflows and identifying areas where automation can have the greatest impact. Organizations should evaluate their specific needs and challenges, allowing them to pinpoint machinery that aligns with production goals while enhancing efficiency. Key considerations include the scale of operations, product types, and the potential return on investment.

Next, businesses must explore various technology solutions that integrate seamlessly with selected machinery. This entails reviewing automation software, real-time data analytics, and Internet of Things (IoT) devices that can optimize operations. Companies should prioritize solutions that offer flexibility and scalability, ensuring that their automation systems can adapt to future changes in demand or production methods. Collaborating with technology providers and conducting pilot tests can further help in selecting the most compatible systems, fostering a smoother transition to automated processes while minimizing disruptions.

Implementing Automation: Steps to Follow and Best Practices

Implementing automation in machinery not only enhances efficiency but also boosts productivity across various industries. According to a report by McKinsey, companies that adopt automation in their operations can see productivity increase by up to 30%. This monumental shift requires a structured approach to ensure successful implementation.

To start, organizations should conduct a thorough assessment of their current processes to identify areas where automation would yield the highest impact. Selecting the right technology is crucial; companies should focus on solutions that integrate seamlessly with existing systems while providing scalability. Moreover, the creation of a cross-functional team responsible for overseeing the automation process ensures that diverse skill sets contribute to the implementation, aligning technology with business objectives.

Tips: Regular training sessions for employees on new technologies can significantly reduce resistance and foster a culture of continuous improvement. Additionally, businesses should prioritize data collection to analyze performance post-implementation, enabling adjustments and optimizations based on real-time insights. As highlighted by a report from the World Economic Forum, companies that embrace such practices can achieve significant competitive advantages in the marketplace.

Machinery Automation Impact on Efficiency

The bar chart above demonstrates the increase in operational efficiency before and after implementing machinery automation. Automation resulted in a significant boost from 60% to 85% efficiency, showcasing the positive impact of automated processes in the manufacturing sector.

Monitoring and Evaluating Automation Performance for Continuous Improvement

Monitoring and evaluating automation performance is crucial for ensuring ongoing efficiency and productivity in any automated system. A report by McKinsey highlights that organizations that actively monitor automation can achieve up to a 30% increase in efficiency compared to those that do not. This improvement can largely be attributed to better resource allocation, reduced downtime, and enhanced process optimization. By implementing key performance indicators (KPIs) that are aligned with the organization’s objectives, businesses can assess the impact of automation on their operations in real-time.

Moreover, continuous improvement through evaluation enables companies to refine their automated systems. A study from the International Society of Automation shows that firms that adapt their automation strategies based on performance data can improve output by as much as 20% annually. Regularly analyzing data from automated processes allows for the identification of bottlenecks and inefficiencies, paving the way for necessary adjustments. Incorporating advanced analytics and machine learning can further enhance these evaluations by predicting future performance and recommending proactive solutions. Therefore, a robust monitoring framework is not just beneficial but essential for sustaining a competitive edge in an increasingly automated landscape.

How to Implement Machinery Automation for Increased Efficiency and Productivity - Monitoring and Evaluating Automation Performance for Continuous Improvement

| Automation Tool | Efficiency Gain (%) | Productivity Increase (%) | Cost Savings (%) | Performance Evaluation Frequency |

|---|---|---|---|---|

| Automated Conveyor System | 15 | 20 | 10 | Monthly |

| Robotic Welding | 20 | 25 | 15 | Bi-Weekly |

| Automated Quality Inspection | 10 | 15 | 5 | Quarterly |

| Automated Packaging System | 18 | 22 | 12 | Monthly |

| Automated Assembly Line | 25 | 30 | 20 | Weekly |

Related Posts

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry

-

2025 Top 5 Food Bagging Machines You Need to Know About

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss

-

Top 10 Industrial Food Packaging Machines for Your Production Line

-

2025 How to Choose the Best Packer Machine for Your Business Needs