The Duravant family of operating companies serve the food processing, packaging and material handling segments.

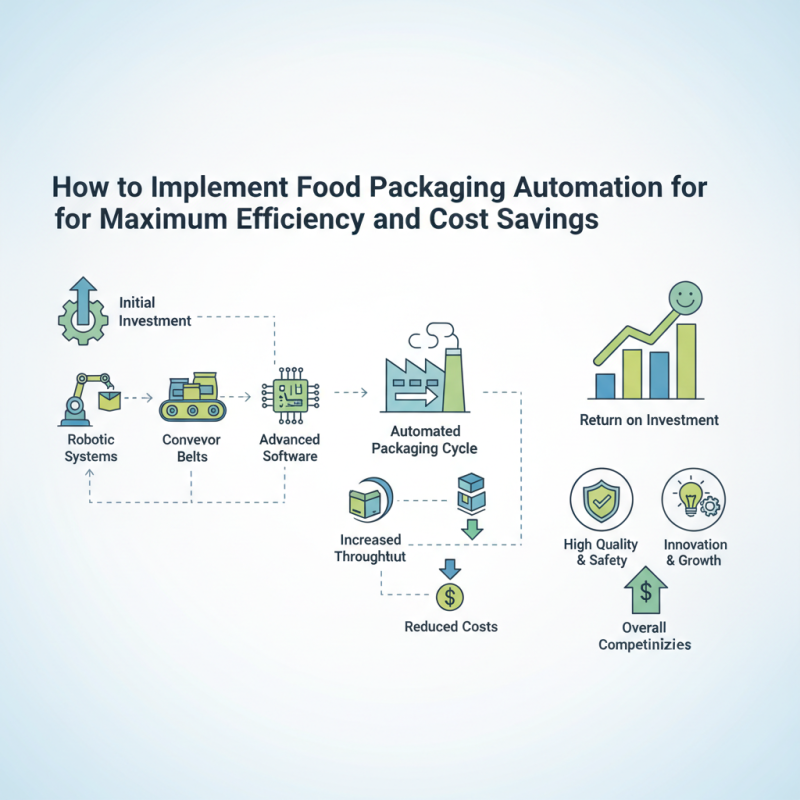

How to Implement Food Packaging Automation for Maximum Efficiency and Cost Savings

In today’s fast-paced food industry, the need for efficiency and cost-effectiveness has never been more critical. One of the most effective ways to achieve these goals is through the implementation of food packaging automation. This innovative approach not only streamlines packaging processes but also minimizes labor costs and reduces the likelihood of human error, ultimately leading to higher quality products and increased throughput. As consumer demand for diverse and convenient food options continues to grow, businesses can greatly benefit from adopting automation technologies in their packaging operations.

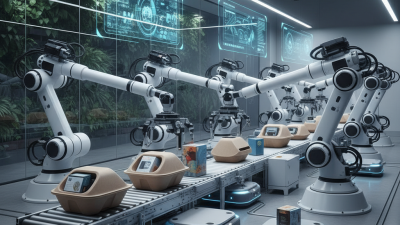

Food packaging automation encompasses a wide range of technologies, including robotic systems, conveyor belts, and advanced software solutions designed to optimize the entire packaging cycle. By integrating these systems, companies can enhance their production capabilities while maintaining high standards of hygiene and safety—a vital aspect of the food industry. Additionally, automating packaging processes frees up valuable human resources, allowing staff to focus on more strategic tasks that can drive innovation and growth.

As we explore the steps to implement food packaging automation effectively, it is essential to consider both the initial investment and the potential return on that investment. With the right strategies, businesses can not only achieve maximum efficiency but also realize significant cost savings that contribute to their overall competitiveness in the marketplace.

Understanding Food Packaging Automation and Its Benefits

Understanding food packaging automation is crucial for modern food production businesses aiming to enhance efficiency and reduce costs. This technology integrates advanced machinery and software to streamline the packaging process, minimizing human intervention while maximizing output. Automated systems can handle tasks such as filling, sealing, and labeling with greater precision and speed than manual methods. This not only increases production rates but also significantly reduces the likelihood of errors, ensuring that each product meets consistent quality standards.

The benefits of food packaging automation extend beyond just speed and accuracy. By implementing automated systems, companies can achieve better inventory management and reduce labor costs. Automation allows for real-time tracking of packaging operations, providing insights that help optimize workflows. Additionally, energy-efficient machines can further lower costs while supporting sustainability initiatives. With reduced reliance on manual labor, businesses can also focus their workforce on more strategic tasks, driving innovation and improving overall productivity within the organization.

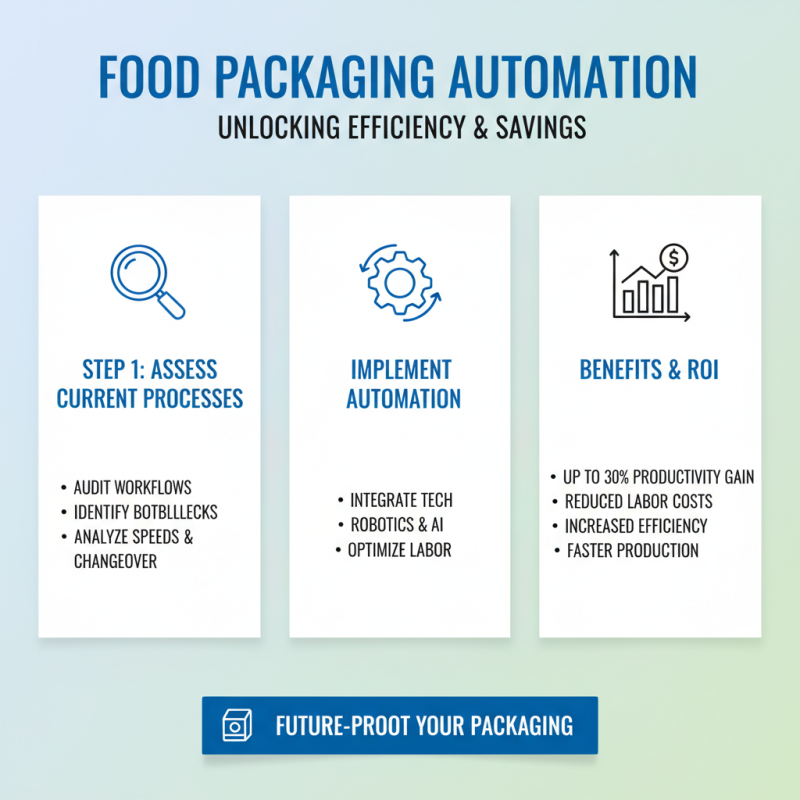

Assessing Current Packaging Processes for Improvement Opportunities

Assessing current packaging processes is a critical first step toward achieving maximum efficiency and cost savings through food packaging automation. According to a report by the Food and Beverage Packaging Market, automated solutions can enhance productivity by up to 30% while significantly reducing labor costs. Companies should begin by conducting a thorough audit of their existing packaging workflows, focusing on identifying bottlenecks, redundancies, and areas for potential technological integration. For instance, by analyzing packaging line speeds, product changeover times, and labor allocation, businesses can uncover opportunities that may not be immediately evident.

Moreover, implementing data analytics to monitor packaging performance is crucial. A study published by the International Packaging Association highlighted that businesses leveraging real-time data can increase their operational efficiency by approximately 25%. Such insights can guide decision-making on machinery upgrades and layout adjustments, ultimately leading to streamlined processes. As automation technologies continue to advance, organizations that dedicate time to assess and refine their current packaging methods stand to gain a competitive edge, reducing costs while also meeting consumer demands for faster and more sustainable packaging solutions.

Selecting the Right Automated Packaging Equipment for Your Needs

Selecting the right automated packaging equipment is crucial for businesses aiming to enhance their operational efficiency. Start by assessing your specific packaging needs, including the types of products you handle, packaging materials, and required output rates. Understanding these factors will help narrow down the equipment options available to you without overspending on unnecessary features. Consider machines that are versatile enough to accommodate product variations, ensuring long-term utility as your product line evolves.

In addition to product specifications, evaluate the scalability and flexibility of the equipment. Automated packaging solutions should not only meet your current demands but also adapt to future growth. Furthermore, prioritize ease of use and maintenance; user-friendly interfaces and readily available support services can significantly reduce downtime and training periods.

Lastly, conducting a cost-benefit analysis will help to gauge the long-term savings from investing in automation versus the initial purchase and installation costs. By methodically selecting the right equipment, businesses can drive productivity improvements while maximizing cost savings.

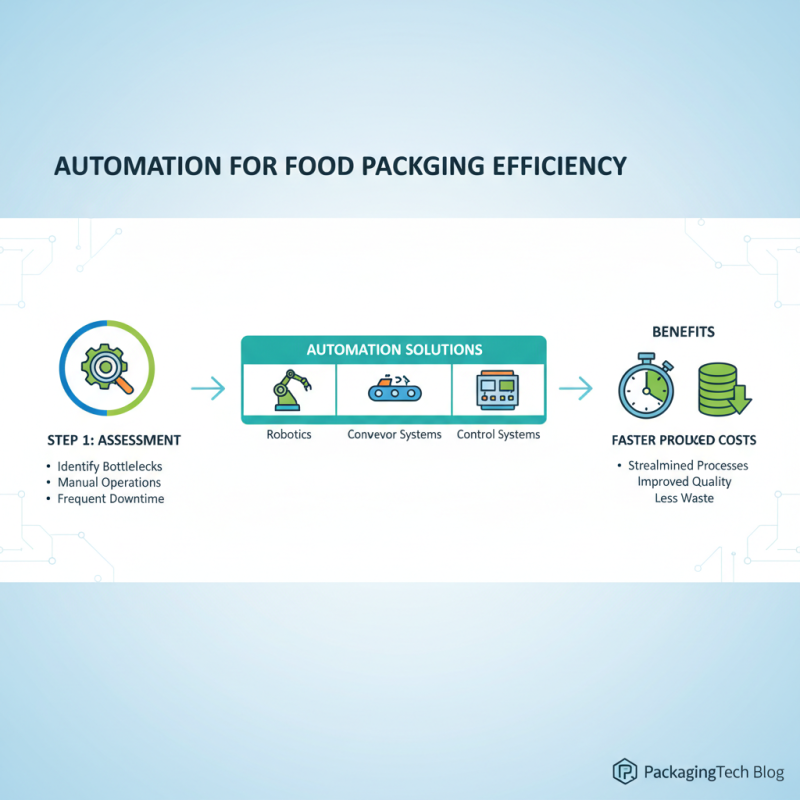

Integrating Automation Solutions into Existing Packaging Lines

Integrating automation solutions into existing packaging lines can significantly enhance efficiency and reduce costs in food packaging operations. The first step in this integration process is a thorough assessment of the current packaging system. It’s essential to identify bottlenecks, manual operations, and areas where downtime occurs frequently. By applying automation technologies, such as robotics and conveyor systems, companies can streamline their processes, allowing for faster production rates without compromising on quality.

Once the system assessment is complete, the next step is to select appropriate automation tools that fit seamlessly into the existing packaging line. This might involve implementing automated filling machines, labeling systems, or even advanced software for inventory and production monitoring. Training staff to operate and maintain these new technologies is crucial. Proper training ensures that the workforce is equipped to adapt to the changes, maximizing the benefits of automation while minimizing disruptions during the transition phase.

Furthermore, ongoing evaluation of the automated processes is vital to adapt to market demands and operational challenges. A feedback loop should be established, allowing teams to monitor performance metrics and make adjustments as necessary. This proactive approach not only sustains operational efficiency but also fosters a culture of continuous improvement, enabling companies to stay competitive in the evolving food packaging landscape.

Measuring Efficiency and Cost Savings Post-Implementation

Measuring efficiency and cost savings after implementing food packaging automation is crucial for understanding the return on investment and the overall impact on production workflows. To effectively assess these metrics, organizations must first establish key performance indicators (KPIs) that align with their specific goals. Common KPIs in this context include production speed, waste reduction, labor costs, and product consistency. By collecting data before and after automation implementation, businesses can create a clear comparison to highlight improvements in operational efficiency.

Moreover, maintaining a continuous monitoring process post-implementation is essential for gaining insights into the long-term benefits of automation. Utilizing real-time analytics allows companies to track performance trends over time, facilitating quick adjustments to optimize processes. Additionally, engaging employees in feedback loops can enhance understanding of any challenges faced during the transition and help refine the automation systems in place. Ultimately, consistent evaluation will not only reveal cost savings gained from reduced labor and waste but also inform strategic decisions for future upgrades or expansions in packaging technology.

Related Posts

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss

-

2025 Top 10 Packaging Systems Innovations to Boost Your Business Efficiency

-

What is a Case Packer and How Does it Work in Packaging Automation

-

Top 10 Benefits of Using a Case Packer Machine in Your Packaging Line

-

2025 Top 10 Packer Machines Revolutionizing Packaging Efficiency with 20 Percent Faster Processing