The Duravant family of operating companies serve the food processing, packaging and material handling segments.

10 Essential Tips for Choosing the Right Case Packer for Your Business

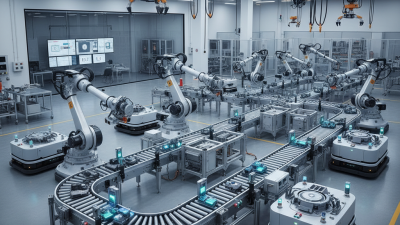

Choosing the right case packer is a crucial decision for any business involved in packaging, as it directly impacts operational efficiency and product presentation. A case packer automates the end-of-line packing process, ensuring that products are securely and consistently packed into cases for shipment or storage. However, navigating the myriad of options available can be overwhelming. To make an informed choice, it is essential to consider various factors, including production volume, product dimensions, and the specific needs of your packaging line.

In this guide, we will explore ten essential tips for selecting the ideal case packer tailored to your business requirements. By understanding the features and capabilities of different case packing systems, you can better align your choice with your workflow and future growth plans. From evaluating the technology and flexibility of the equipment to considering the integration with existing systems, these tips will provide valuable insights to help you make a strategic investment that enhances productivity and ultimately contributes to your bottom line.

Factors to Consider When Selecting a Case Packer for Your Production Line

When selecting a case packer for your production line, it is crucial to consider several key factors to ensure it aligns with your business needs. First and foremost, assess the types of products you are packaging. The dimensions, weight, and fragility of your items will significantly influence the design and specifications of the case packer. For instance, delicate products may require custom packing solutions to prevent damage during the packaging process, while heavier items may necessitate robust machinery capable of handling greater loads.

Another vital consideration is the production speed and output requirements. Evaluate your production goals and determine how quickly you need the case packer to operate to meet demand. This involves understanding the throughput of your current line and predicting future growth. Additionally, flexibility is paramount; choose a case packer that can accommodate various packaging styles and sizes. This adaptability will allow your business to respond to changing customer demands without necessitating further investment in new machinery. Ultimately, thorough assessment of product specifics and production capability will guide you in selecting the most efficient case packer for your operations.

Understanding Different Types of Case Packers and Their Applications

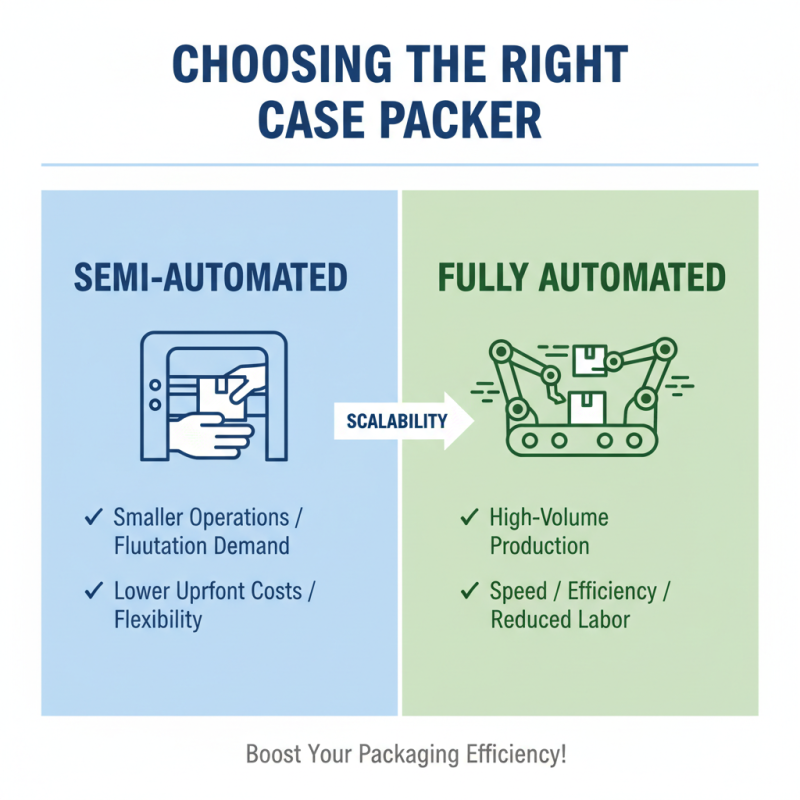

When it comes to selecting the right case packer for your business, understanding the various types available and their applications is paramount. Case packers can generally be categorized into semi-automated and fully automated systems. Semi-automated case packers are ideal for smaller operations or those experiencing fluctuating demand, as they offer flexibility and lower upfront costs. On the other hand, fully automated case packers are suitable for high-volume production environments, providing speed and efficiency while minimizing labor costs.

One essential tip to consider is to assess the types of products you will be packing. For fragile items or those requiring special handling, a gentle case packing solution may be necessary. Alternatively, for robust products, a high-speed case packer that can handle significant throughput might be more appropriate. Additionally, it's crucial to evaluate the configuration of your production line. Ensure that the case packer you choose integrates well with your existing machinery to maintain workflow efficiency.

Lastly, consider the future scalability of your operations. Selecting a case packer that can be easily upgraded or scaled can save you time and resources as your business grows. Investing in adaptable machinery will help you meet changing market demands without the need for a complete overhaul of your packing system. By focusing on these elements, you'll be better equipped to choose a case packer that aligns with both your current needs and future aspirations.

Evaluating Case Packer Speed: How to Match Your Output Requirements

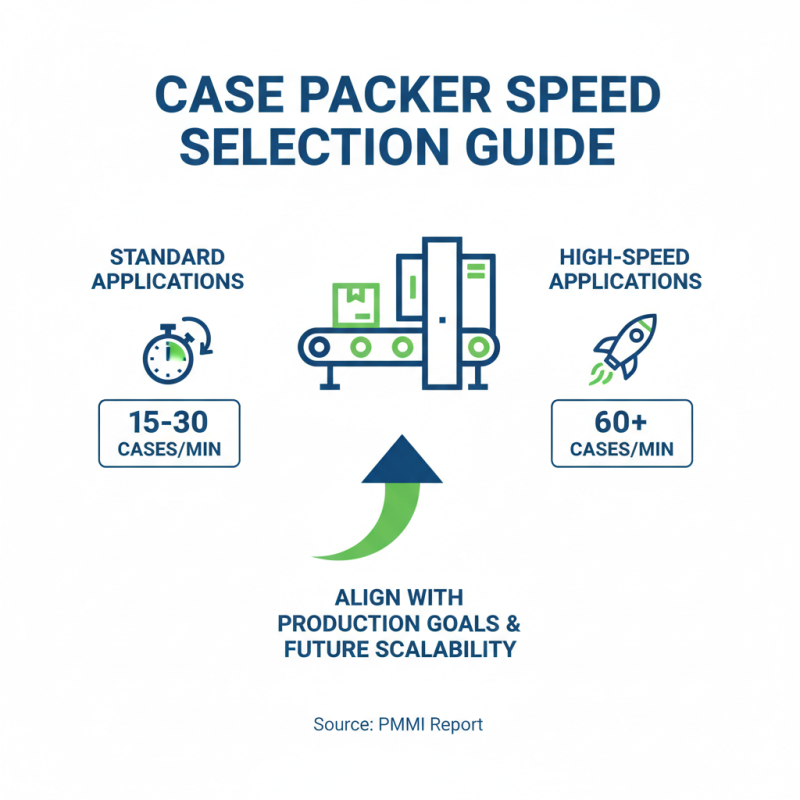

When considering the speed of a case packer, it is essential to align its capabilities with your business's production objectives. According to a recent report from the Packaging Machinery Manufacturers Institute (PMMI), the average speed of case packers ranges from 15 to 30 cases per minute for standard applications, while high-speed options can achieve speeds upwards of 60 cases per minute. Understanding your output requirements is crucial for selecting a system that not only meets current demands but also allows for future scalability as your production needs evolve.

Evaluating your production line’s integration is another critical aspect. The total output of your packaging system should account for the output of adjacent processes, from filling to sealing. Industry experts suggest that maintaining a balanced flow throughout the production line can minimize bottlenecks. A well-timed case packer must be synchronized with upstream and downstream equipment to ensure continuous workflow, enhancing overall efficiency. Studies indicate that optimizing this integration can lead to productivity increases of up to 25%, making it vital to consider both speed and compatibility during the selection process.

Cost Analysis: Balancing Initial Investment vs. Long-Term Efficiency

When selecting a case packer for your business, the decision often hinges on a cost analysis that weighs the initial investment against long-term efficiency. It’s essential to consider not only the price tag of the equipment but also the value it brings over time. For instance, a more expensive case packer might offer advanced features such as higher speed, flexibility in handling various package types, and lower energy consumption, which could result in significant cost savings in operational expenses down the line.

In the long run, the most economical choice may not always be the one with the lowest initial cost. Evaluating maintenance costs, potential downtime, and the impact on labor can all play a critical role in determining the true financial benefit of your investment. By prioritizing efficiency and reliability, you can ensure that the case packer you select not only meets your current needs but also adapts to future demands, ultimately contributing to the sustainability and growth of your business.

This chart illustrates the initial investment cost and annual efficiency savings associated with different case packer models. As observed, the basic model requires the lowest initial investment, but it also provides the least savings in efficiency compared to more advanced models.

Maintenance and Support: Ensuring Longevity of Your Case Packer Investment

When investing in a case packer for your business, prioritizing maintenance and support is crucial for maximizing its longevity and performance. Regular maintenance is not only essential for keeping the machinery in optimal working condition but also helps in avoiding unexpected breakdowns. Establishing a routine maintenance schedule, which includes inspections, cleaning, and timely replacements of worn parts, can significantly extend the lifespan of your equipment.

In addition to proactive maintenance, having reliable support from your case packer provider is vital. A robust support system ensures that you have access to technical assistance, spare parts, and repair services whenever needed. This responsiveness can minimize downtime, which is critical in a fast-paced production environment. Moreover, conducting training sessions for your staff on operational best practices can further enhance the efficiency and durability of the case packer, ensuring that your investment continues to deliver optimal performance over the years.

Related Posts

-

How to Choose the Right Industrial Packaging Equipment for Your Business

-

2025 Top 5 Food Bagging Machines You Need to Know About

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

How to Implement Machinery Automation for Increased Efficiency and Productivity

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management

-

2025 Top 10 Packaging Systems Innovations to Boost Your Business Efficiency