The Duravant family of operating companies serve the food processing, packaging and material handling segments.

How to Choose the Right Industrial Packaging Equipment for Your Business

Choosing the right industrial packaging equipment is a critical decision for businesses aiming to optimize operational efficiency and product safety. According to a recent report by MarketsandMarkets, the global industrial packaging market is expected to reach a value of $780 billion by 2025, growing at a CAGR of 4.4%. This expansion emphasizes the importance of selecting appropriate packaging solutions that not only meet regulatory requirements but also enhance the supply chain processes.

Industry experts highlight the significant role that industrial packaging equipment plays in overall productivity. As noted by John Smith, a leading expert in packaging technology, “The right industrial packaging equipment can make or break the efficiency of a supply chain, influencing everything from cost savings to product integrity.” This underscores the necessity for businesses to carefully assess their packaging needs and invest in equipment that aligns with their operational goals.

By understanding various options available, such as automated packing systems, stretch wrapping machines, and custom packaging solutions, companies can make informed decisions. In today’s competitive marketplace, leveraging the right industrial packaging equipment can lead to enhanced productivity, reduced waste, and improved customer satisfaction, ensuring a sustainable advantage in the industry.

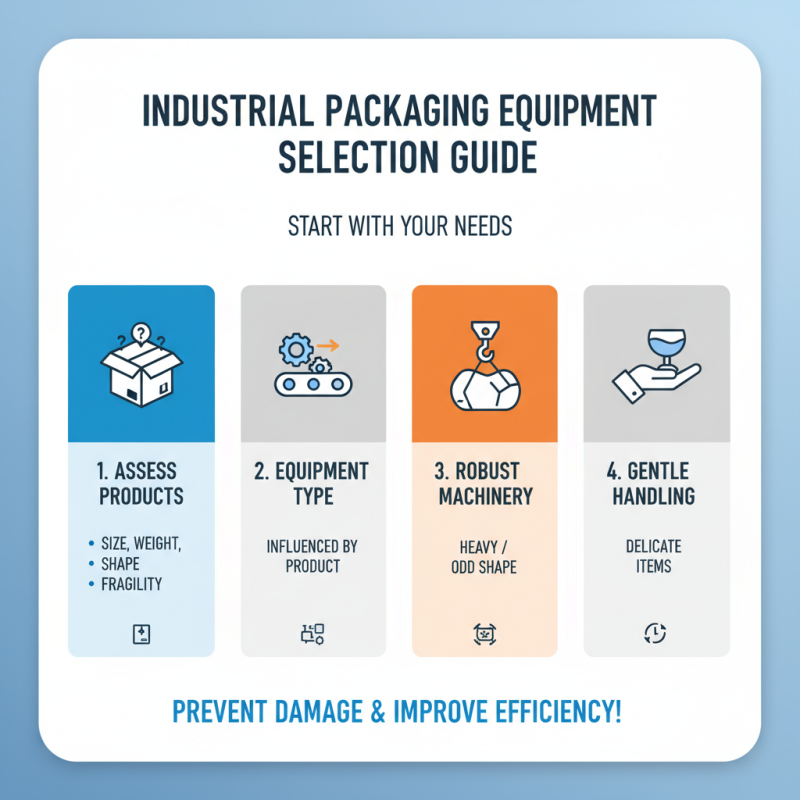

Understanding Your Packaging Needs and Requirements

When selecting industrial packaging equipment, it is crucial to start by understanding your specific packaging needs and requirements. Begin by evaluating the type of products you will be packaging. Consider factors such as size, weight, shape, and fragility, as these characteristics will influence the type of equipment suitable for your operations. For instance, products that are heavy or oddly shaped may require more robust machinery, whereas delicate items may need gentle handling equipment to prevent damage.

Additionally, think about your production volume and speed requirements. If your business demands high throughput, automated packaging solutions can significantly enhance efficiency and reduce labor costs. Assess the range of packaging formats you require, including bulk packaging, shrink wrapping, or carton sealing. By thoroughly analyzing these elements, you can narrow down your choices and select equipment that not only meets your current needs but can also adapt to future demands as your business grows.

Evaluating Different Types of Industrial Packaging Equipment

When evaluating different types of industrial packaging equipment, it is essential to consider the specific needs and demands of your business. The North American food packaging equipment market, for example, is projected to grow from $4.32 billion in 2022 to $5.54 billion by 2029, reflecting a compound annual growth rate (CAGR) of 3.6%. This growth underscores the importance of selecting equipment that not only meets current demands but also anticipates future changes in the market.

Furthermore, the packaging testing equipment market is set to expand from $3.33 billion in 2021 to $5.11 billion by 2028, with a CAGR of 6.3%. This significant increase indicates that businesses need reliable packaging testing solutions to ensure product integrity and compliance with industry standards. When choosing industrial packaging equipment, companies must weigh these market forecasts alongside their operational requirements to select machinery that enhances efficiency and sustainability while accommodating diverse materials.

Assessing Compatibility with Existing Production Processes

When selecting industrial packaging equipment, assessing its compatibility with your existing production processes is crucial. According to a report from Smithers Pira, nearly 70% of manufacturers consider compatibility as one of the top three priorities when investing in new packaging technologies. This alignment not only ensures smooth integration but also minimizes disruption during the transition phase. Equipment that fits seamlessly into existing workflows can significantly enhance productivity and reduce training times for employees.

Moreover, an analysis by the Freedonia Group indicates that companies that prioritize compatibility typically experience a 15-20% decrease in operational costs. Mechanisms that can easily interface with current systems allow for the preservation of capital already invested in infrastructure. It is essential to evaluate factors such as the speed of existing machinery, the type of products being packaged, and the required levels of automation. A comprehensive assessment will help in selecting equipment that not only meets immediate packaging needs but also supports future production scalability.

How to Choose the Right Industrial Packaging Equipment for Your Business

The chart above illustrates the assessment scores for various factors to consider when choosing industrial packaging equipment. The scores range from 0 to 100, indicating how well each factor meets business needs. Equipment compatibility scores positively highlight the importance of integrating with existing production processes.

Analyzing Cost Efficiency and Budget Considerations

When selecting the appropriate industrial packaging equipment,

cost efficiency and

budget considerations play a pivotal role

in decision-making. A recent report from the Packaging Machinery Manufacturers Institute (PMMI)

indicates that packaging equipment can account for up to 15% of a company's total production costs.

Thus, businesses must evaluate the return on investment (ROI) when considering new machinery.

Efficient machines may have a higher upfront cost but can lead to significant savings through

reduced labor, increased throughput, and minimized

material waste over time.

Furthermore, it's essential to analyze total cost of ownership (TCO),

which includes maintenance, operational expenses, and energy consumption. According to a study by the

Freedonia Group, companies that invest in high-quality, energy-efficient packaging solutions

can reduce their operational costs by as much as 20% annually.

This data highlights the importance of not just looking at the initial price tag but considering

long-term savings and efficiency gains.

Ultimately, making informed decisions based on comprehensive cost evaluations will lead to

better financial outcomes and enhanced operational capabilities for businesses in the

competitive packaging landscape.

Researching Reliable Suppliers and Manufacturers

When selecting industrial packaging equipment, one of the crucial steps is researching reliable suppliers and manufacturers. A dependable supplier can significantly impact the efficiency and durability of your packaging process. Begin by evaluating potential suppliers based on their experience in the industry, product quality, and customer service. Look for companies that have a proven track record and positive reviews from other businesses.

**Tips:** Consider requesting samples or demonstrations to better understand the equipment provided by each supplier. This hands-on approach can help you gauge the quality and suitability for your business needs. Additionally, ensure that the suppliers offer comprehensive support, such as training and maintenance services, to help you maximize your investment.

Another essential aspect of your research should involve assessing the suppliers' compliance with industry standards and regulations. This can provide peace of mind that the equipment will not only function effectively but also adhere to safety and quality benchmarks. Ultimately, choosing a supplier who prioritizes transparency and accountability will foster a long-term partnership that can benefit your operations.

**Tips:** Compile a list of questions to ask potential suppliers regarding their products, warranties, and support services. This will aid in making a well-informed decision while establishing clear expectations right from the start.

How to Choose the Right Industrial Packaging Equipment for Your Business - Researching Reliable Suppliers and Manufacturers

| Feature | Importance | Considerations | Cost Range |

|---|---|---|---|

| Type of Packaging Equipment | High | Suitability for products, automation level | $5,000 - $100,000 |

| Supplier Reputation | High | Customer reviews, industry experience | N/A |

| Technical Support | Medium | Availability of support, training offered | $500 - $5,000 |

| Maintenance Requirements | Medium | Frequency of maintenance, parts availability | $1,000 - $10,000/year |

| Customization Options | Low | Flexibility for specific needs | Varies widely |

Related Posts

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry

-

2025 Top 10 Packaging Systems Innovations to Boost Your Business Efficiency

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss

-

2025 Top 10 Packer Machines Revolutionizing Packaging Efficiency with 20 Percent Faster Processing

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management

-

2025 Top 5 Food Bagging Machines You Need to Know About