The Duravant family of operating companies serve the food processing, packaging and material handling segments.

2025 How to Choose the Best Packer Machine for Your Business Needs

In the rapidly evolving landscape of industrial packaging, selecting the right packer machine has become crucial for businesses aiming to enhance efficiency and reduce operational costs. According to a recent report by MarketsandMarkets, the global packaging machinery market is projected to grow from $46.3 billion in 2020 to $70.5 billion by 2025, highlighting the increasing importance of advanced packaging solutions. As companies strive to keep pace with consumer demands and sustainability practices, understanding the various types of packer machines available is essential for making informed decisions.

Industry experts emphasize the significance of this selection process. "Choosing the appropriate packer machine can significantly impact production speed and product integrity," states Dr. John Smith, a renowned packaging technology specialist at Packaging Innovations Consortium. His insights reflect a growing consensus that investing in the right technology not only boosts productivity but also enhances product quality and customer satisfaction.

As you explore options for your business, consider factors such as machine versatility, operational efficiency, and integration capabilities. The decision-making process for a packer machine should align with your specific business needs and long-term goals, ensuring that your investment supports your operations in an increasingly competitive market.

Overview of Packer Machines and Their Importance in Business

Packer machines play a crucial role in various industries, ensuring that products are efficiently packaged for distribution and sale. These machines not only streamline the packaging process but also enhance overall productivity by minimizing labor costs and reducing the likelihood of human error. In fast-paced environments, where time and accuracy are paramount, the importance of selecting the right packer machine cannot be overstated.

The importance of packer machines extends beyond mere efficiency; they are vital for maintaining product integrity. Proper packaging protects goods from damage during transport and storage, and can also prolong shelf life. Additionally, visually appealing packaging can attract customers and serve as a powerful marketing tool. Businesses must carefully consider their specific needs—such as the type of product, production volume, and desired packaging method—when selecting the best packer machine to ensure it aligns with their operational goals and enhances their competitive edge in the market.

Key Factors to Consider When Choosing a Packer Machine

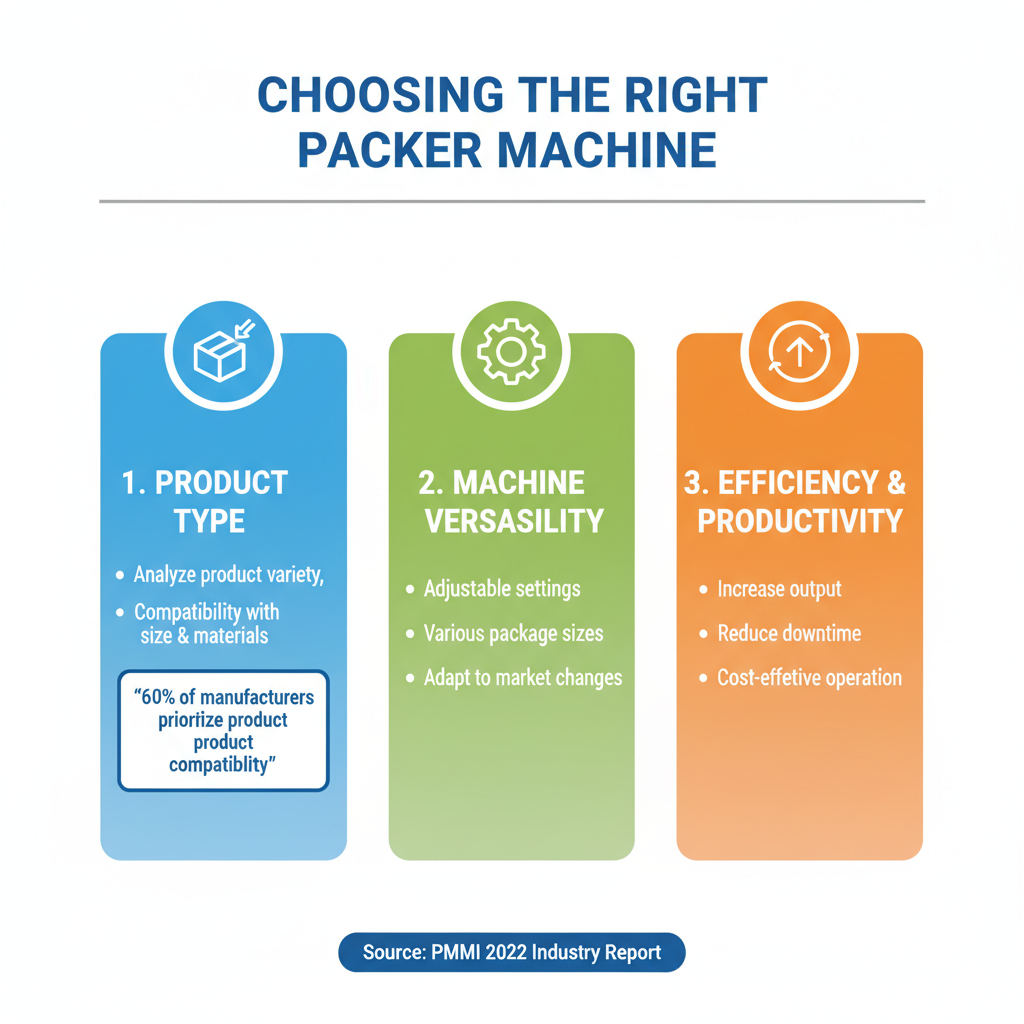

When selecting the best packer machine for your business needs, it’s crucial to consider several key factors that can significantly impact efficiency and productivity. First, analyze the type of products you will be packaging. According to a 2022 industry report by the Packaging Machinery Manufacturers Institute (PMMI), over 60% of manufacturers cite compatibility with product variety as a primary concern when investing in new machinery. Machines that offer adjustable settings for various package sizes and materials can enhance versatility, allowing businesses to adapt to changing market demands.

Another vital consideration is the automation level of the packer machine. A 2023 survey by Research and Markets found that automating packaging processes can lead to a 30% increase in operational efficiency. Businesses should evaluate whether they require fully automated solutions or semi-automated machines based on production volume and labor costs. Additionally, investigating integration capabilities with existing production lines and software systems remains essential, as seamless connections can streamline workflows and reduce potential downtime, further benefiting overall productivity.

Types of Packer Machines and Their Applications in Different Industries

When selecting a packer machine, understanding the various types available and their specific applications across different industries is crucial.

For instance, vertical form-fill-seal machines are popular in the food sector, particularly for packaging snacks, grains, and liquids. These machines offer high efficiency and are capable of producing bags with the desired dimensions, ensuring that products remain fresh and appealing. Furthermore, their compact design allows them to fit easily into production lines with limited space.

In the industrial sector, case packing machines are essential for packaging bulk items into boxes or cases, facilitating easier transportation and storage. They cater to various products, from beverages to household goods, and are designed for high-speed operations.

Additionally, shrink wrap machines are widely used in retail and logistics for securing products on pallets. These machines provide protection from dust and damage while maintaining a neat presentation. By understanding the specific role of each machine type, businesses can make informed decisions that align with their operational needs and production goals.

Cost Analysis: Budgeting for Your Ideal Packer Machine

When selecting the best packer machine for your business needs, conducting a thorough cost analysis is critical. Understanding variable costs—expenses that fluctuate with production levels—will help you gauge how much you can allocate for the ideal machinery. For instance, as production ramps up, so do costs related to materials, labor, and maintenance. Accurately calculating these variable costs ensures that you budget effectively for a packer machine that aligns with your operational scale and financial capabilities.

Additionally, consider the emerging trend of Machinery-as-a-Service (MaaS). This innovative model allows businesses to engage packaging machinery without the heavy upfront costs typically associated with purchasing equipment. By opting for MaaS, your operation could minimize capital expenses and share risk with suppliers, providing a more flexible budgeting solution. This could be particularly beneficial as your production volume changes, enabling you to keep pace without overextending your financial resources. Evaluating both traditional purchasing and MaaS will be essential in making a financially sound decision for your packaging needs.

2025 How to Choose the Best Packer Machine for Your Business Needs - Cost Analysis: Budgeting for Your Ideal Packer Machine

| Machine Type | Average Cost ($) | Speed (Packages/Minute) | Power Requirement (kW) | Warranty Period (Years) |

|---|---|---|---|---|

| Vertical Packer | 5,000 | 30 | 1.5 | 2 |

| Horizontal Packer | 8,000 | 50 | 2.0 | 3 |

| Semi-Automatic Packer | 4,000 | 20 | 1.2 | 1 |

| Fully Automatic Packer | 15,000 | 100 | 4.0 | 5 |

| Compact Packer | 3,500 | 15 | 1.0 | 2 |

Maintenance and Support: Ensuring Longevity of Your Packer Equipment

When investing in packing machinery, understanding the importance of maintenance and support is crucial for ensuring the longevity of your equipment. Regular maintenance not only helps in preventing unexpected breakdowns but also promotes optimal performance. Implementing a routine maintenance schedule can significantly extend the lifespan of your packer machine, allowing you to maximize your investment.

**Tips:** Establish a maintenance checklist that covers essential tasks such as lubrication, inspection of wear parts, and calibration checks. Moreover, train your staff on proper handling techniques to mitigate the risk of damage during operation.

Additionally, choose a manufacturer or supplier that offers robust customer support and accessibility to spare parts. This ensures that you can quickly rectify any issues that arise, minimizing downtime in your production line. The availability of technical assistance can be a game-changer, especially when dealing with complex machinery.

**Tips:** Before finalizing your purchase, inquire about the warranty terms and the availability of service technicians. Having access to expert support will not only provide peace of mind but also ensure that your machinery maintains peak efficiency throughout its operational life.

2025 Packer Machine Maintenance Costs

This bar chart illustrates the estimated annual maintenance costs for different types of packer machines based on their features. Understanding these costs can help businesses choose the right equipment for their needs, ensuring longevity and efficiency.

Related Posts

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

2025 Top 10 Packaging Systems Innovations to Boost Your Business Efficiency

-

2025 Top 5 Food Bagging Machines You Need to Know About

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management