The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What is a Case Packer and How Does it Work in Packaging Automation

In the ever-evolving world of packaging automation, the case packer stands out as a fundamental component that enhances efficiency in the packaging process. A case packer is a sophisticated machine designed to automate the task of placing products into shipping cases or containers. This not only increases speed and precision but also helps in reducing labor costs and minimizing human error. As businesses strive for greater productivity and streamlined operations, understanding how a case packer works becomes essential for optimizing packaging lines.

The functionality of a case packer varies depending on the specific needs of the production line, but the core process involves loading items into the designated cases with remarkable accuracy. This automation aids manufacturers across various industries in meeting high demands while maintaining quality standards. By incorporating advanced technologies such as robotics and sensors, modern case packers significantly improve the speed and reliability of packaging processes. As we delve deeper into the workings of case packers, we will explore their different types, operational mechanisms, and the advantages they bring to the table in packaging automation.

What is a Case Packer in Packaging Automation?

A case packer is a crucial component in packaging automation systems, designed to streamline the process of packing products into cases for shipping or storage. Typically utilized in industries such as food and beverage, pharmaceuticals, and consumer goods, case packers enhance efficiency by reducing manual labor and increasing packaging accuracy. According to a report by Smithers Pira, the global market for automated packaging solutions is projected to grow significantly, reaching $30 billion by 2027, highlighting the rising adoption of technologies such as case packers.

In operation, case packers use various mechanisms, including robotics and conveyor systems, to transport products from production lines to packaging areas. These machines can handle different packaging formats, such as trays, boxes, and cartons, ensuring flexibility to adapt to diverse product types. Industry data indicates that implementing automated case packing can increase production rates by up to 50%, while simultaneously reducing errors associated with manual packing. The integration of sensors and smart technology within case packers also allows for real-time monitoring and adjustments, further optimizing the packaging process.

As businesses seek to enhance their operational efficiency and meet the growing demand for quick and accurate packaging solutions, the role of case packers remains integral in the landscape of packaging automation. Their ability to reduce labor costs and improve speed while maintaining high standards of product handling makes them an invaluable asset for manufacturers aiming to compete in a fast-paced marketplace.

Case Packer Efficiency in Packaging Automation

This chart shows the efficiency of different types of case packers in terms of cases per minute. It highlights the performance variations across robotic, semi-automated, and manual packing systems.

The Role of Case Packers in Modern Packaging Lines

Case packers play a pivotal role in modern packaging lines, acting as the bridge between product assembly and distribution. As industries demand higher efficiency and speed in their operations, case packers have become essential components of automated packaging systems. According to a recent report by MarketsandMarkets, the global case packing market is projected to reach $5.57 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.8% from 2020. This growth highlights the increasing need for automation in handling products, helping manufacturers keep up with consumer demands while minimizing labor costs.

In a typical packaging line, case packers automate the process of placing products into boxes or cases, thereby streamlining operations and reducing the risk of human error. Data from the Freedonia Group indicates that automated case packing systems can improve productivity by as much as 25%, enabling companies to enhance their throughput. Moreover, the integration of robotics and advanced technology in case packing processes allows for greater flexibility in handling a variety of product shapes and sizes, which is crucial as more businesses pivot toward customization and smaller batch productions. This adaptability not only meets the challenges of e-commerce but also aligns with sustainability goals by optimizing packaging materials and reducing waste.

What is a Case Packer and How Does it Work in Packaging Automation - The Role of Case Packers in Modern Packaging Lines

| Feature | Description | Benefits |

|---|---|---|

| Automation Level | Fully automated systems that can operate with minimal human intervention. | Improved efficiency, reduced labor costs, and minimized errors. |

| Speed | Can pack cases at speeds of up to 25 cases per minute. | Increased throughput and reduced cycle time. |

| Flexibility | Able to handle various case sizes and shapes. | Adaptability to different production requirements. |

| Integration | Easily integrates with existing packaging lines and systems. | Seamless operation and improved overall productivity. |

| Maintenance | Requires regular maintenance to ensure optimal performance. | Prevents breakdowns and prolongs equipment lifespan. |

How Case Packers Operate: Mechanisms and Technology Explained

Case packers are essential components in the realm of packaging automation, designed to significantly enhance efficiency in the packaging process. They operate through a combination of mechanical systems and technology, which work together seamlessly to assemble products into cases or cartons. The main mechanism involves product accumulation, where individual items are gathered on a conveyor and organized into predetermined configurations. These configurations are then guided into a case by automated arms or pusher systems, reducing the need for manual handling.

The technology behind case packers includes sensors and programmable logic controllers (PLCs) that monitor the packaging process in real-time. Sensors detect the position and orientation of products, while PLCs ensure that the case packer operates at optimal speed, adjusting to variations in product flow. Additionally, modern case packers can incorporate robotic arms for greater flexibility and precision, allowing them to adapt to different packaging requirements without significant downtime. Enhanced imaging and vision systems further refine the sorting and packing process, ensuring that products are packaged correctly and efficiently, ultimately minimizing waste and improving overall productivity.

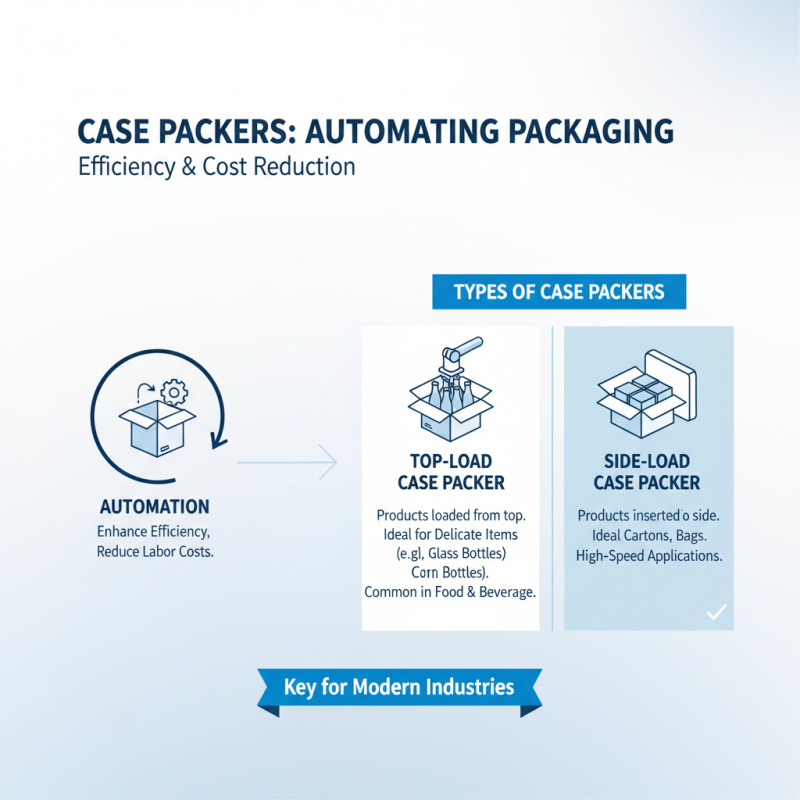

Types of Case Packers and Their Applications in Industries

Case packers are essential in various industries, automating the packaging process to enhance efficiency and reduce labor costs. There are several types of case packers, each tailored to specific applications. For instance, top-load case packers, commonly used in the food and beverage industry, enable products to be loaded from the top into the box, ensuring a secure fit. This type of case packer is ideal for handling delicate items, such as glass bottles, that require gentle handling during packing.

Another prevalent type is the side-load case packer, which works efficiently for larger products or those requiring a particular orientation within the packaging. This design is often employed in pharmaceuticals and personal care products, where precision is paramount. Lastly, robotic case packers utilize advanced technology and flexibility to handle diverse packaging needs across different industries. Their ability to adapt to varying product shapes and sizes makes them highly versatile, streamlining packaging operations in sectors like cosmetics, electronics, and household goods. These innovations in case packing play a crucial role in meeting the demands of modern production environments.

Benefits of Using Case Packers in Packaging Processes

Case packers play a vital role in modern packaging automation, significantly enhancing efficiency in production lines. By automating the packaging process, case packers reduce labor costs and minimize human errors. According to the Packaging Machinery Manufacturers Institute (PMMI), nearly 70% of manufacturing companies reported increased productivity levels after integrating case packers into their operations. These machines quickly and precisely load products into cases, which streamlines workflows and allows workers to focus on more complex tasks.

The benefits of using case packers extend beyond just operational efficiency. A study from Allied Market Research suggests that automated packaging solutions, such as case packers, can lead to a 30% reduction in packaging waste due to better material handling and more accurate filling processes. Furthermore, case packers improve the consistency and quality of packaging, which is critical for maintaining brand reputation and customer satisfaction. Organizations leveraging such technology can respond better to fluctuating market demands, ultimately driving revenue growth and enhancing competitiveness in a rapidly evolving landscape.

Related Posts

-

2025 Top 10 Packer Machines Revolutionizing Packaging Efficiency with 20 Percent Faster Processing

-

10 Essential Tips for Choosing the Right Case Packer for Your Business

-

How to Implement Machinery Automation for Increased Efficiency and Productivity

-

Top 10 Industrial Food Packaging Machines for Your Production Line

-

2025 Top 5 Food Bagging Machines You Need to Know About

-

2025 How to Choose the Right Packing Equipment for Efficient Supply Chain Management