The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Top 10 Benefits of Using a Case Packer Machine in Your Packaging Line

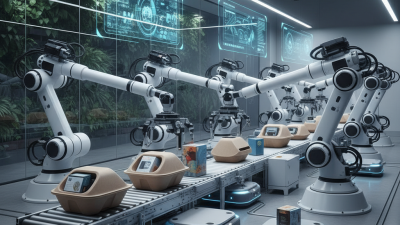

In today's fast-paced manufacturing environment, efficiency and precision are essential for maintaining a competitive edge. The integration of automation in packaging processes has transformed the landscape, with the case packer machine emerging as a key player in enhancing productivity across various industries. This cutting-edge technology not only streamlines the packaging operation but also minimizes labor costs and reduces the risk of errors. As businesses seek innovative solutions to meet growing consumer demands, the case packer machine stands out by offering a range of benefits that can significantly improve packaging lines.

By automating the packing of products into cases, companies can achieve higher throughput while maintaining consistent quality and safety standards. The efficiency gained from implementing a case packer machine allows for quicker turnaround times, making it possible to respond swiftly to market changes. Moreover, modern case packers are designed to accommodate a variety of product sizes and types, showcasing their versatility and adaptability in dynamic production environments. As we explore the top benefits of utilizing a case packer machine, it becomes clear that this investment is crucial for companies aiming to enhance their operational efficiency and overall performance in the packaging sector.

Benefits of Automation in Packaging with Case Packer Machines

The integration of case packer machines into packaging lines offers significant advantages that stem from automation. According to a recent report by the Freedonia Group, the automation of packaging processes can lead to operational efficiency improvements of up to 30%. This allows companies to not only enhance their throughput but also reduce the likelihood of errors that come with manual packing processes. By automating repetitive tasks, manufacturers can allocate their human resources toward more strategic operations, thereby increasing overall productivity.

Furthermore, the implementation of case packer machines contributes to improved consistency and quality control. A study by PMMI, the Association for Packaging and Processing Technologies, found that automated systems reduce the variance in packaging dimensions and pack integrity, resulting in fewer product damages during transportation. This consistency not only minimizes waste but also strengthens brand reliability, as consumers receive products that meet their quality expectations every time. Additionally, automation helps in achieving better ergonomics on the packaging floor, reducing physical strain on workers and enhancing workplace safety, which is pivotal in fostering a healthy work environment.

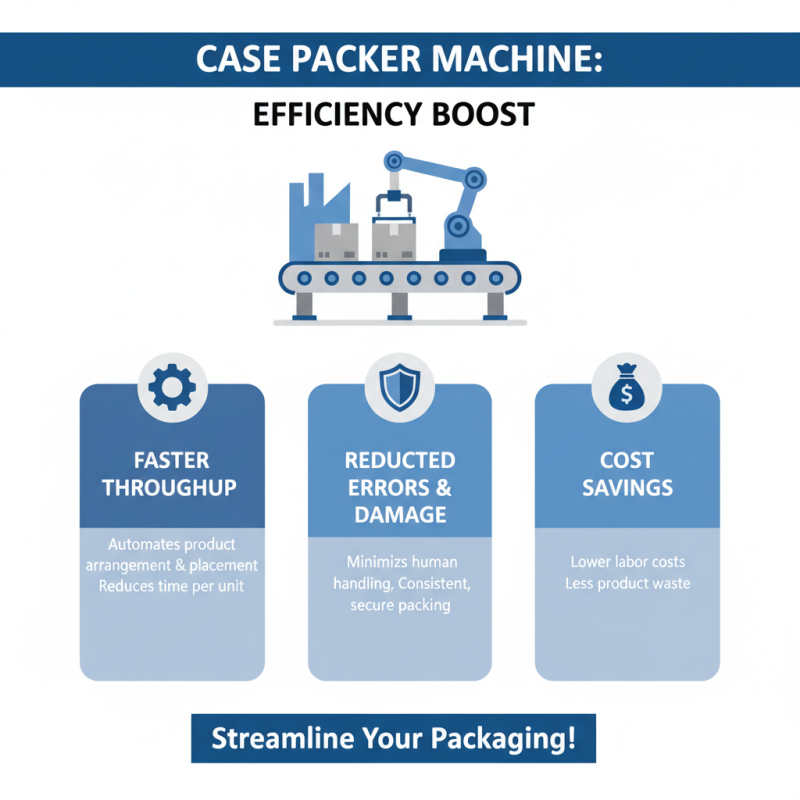

Enhanced Efficiency and Productivity in Packaging Lines

In today's fast-paced manufacturing environment, efficiency and productivity are paramount. The integration of a case packer machine in packaging lines significantly enhances these aspects by streamlining the entire packing process. Unlike manual packing, which can be time-consuming and prone to human error, a case packer automates the arrangement and placement of products into cases, allowing for faster throughput. This not only reduces the labor costs associated with manual packing but also minimizes the risks of damage to products that can occur during handling.

Moreover, the precision of a case packer machine contributes to consistent packing quality, ensuring that each case is filled and sealed correctly. This uniformity leads to fewer returns and improved customer satisfaction as products are delivered intact and on time. By optimizing space and resources, manufacturers can efficiently scale their operations to meet increasing demand without sacrificing quality. Consequently, the enhanced efficiency and productivity achieved through the use of case packer machines empower businesses to stay competitive in a rapidly evolving market.

Reduction of Labor Costs through Automation of Case Packing

The integration of a case packer machine into your packaging line can significantly reduce labor costs, primarily through the automation of the case packing process. In traditional packaging setups, manual labor often requires significant staffing levels, which can lead to higher expenses due to wages, benefits, and training requirements. By utilizing a case packer, companies can streamline their operations, reduce the number of workers needed for packing tasks, and reallocate labor to more strategic areas of the production line.

Automation in case packing not only minimizes labor costs but also enhances efficiency and productivity. With a case packer, tasks that would normally take multiple employees hours to complete can be accomplished in a fraction of the time. This increased speed allows companies to meet higher demand without the corresponding rise in labor costs. Furthermore, automation reduces the risk of human error, resulting in more consistent packaging quality and fewer product losses due to mispacking or handling mistakes. As a result, businesses can achieve a higher return on investment while maintaining the flexibility to adapt to market changes without increasing their workforce.

Improved Product Protection and Reduced Damage Rates

In the fast-paced world of packaging, ensuring product protection is paramount, and using a case packer machine significantly enhances this aspect. With the ability to efficiently pack products into cases, these machines help to minimize human error, which is often a key contributor to product damage during transit. According to industry reports, the implementation of automated packing systems can reduce damage rates by up to 30% compared to manual packing processes. This improvement is vital, as damaged goods can lead to significant financial losses and tarnish a brand's reputation.

Moreover, case packer machines provide consistent packaging that adheres to predetermined specifications, ensuring that each product is securely packed. This consistency not only improves the overall protection of the products but also facilitates better stacking and storage during transportation. A recent study indicated that approximately 25% of product damages occur due to improper packaging and handling.

Automated solutions help mitigate these risks by streamlining packaging operations, thereby significantly reducing the likelihood of damage and enhancing product integrity throughout the supply chain. In an environment where customer satisfaction is heavily dependent on product quality, investing in technology that ensures robust protection is crucial for any packaging line.

Flexibility and Adaptability for Various Packaging Needs

In today's fast-paced packaging industry, flexibility and adaptability are essential for meeting diverse consumer demands. A case packer machine offers significant advantages in these areas, allowing companies to efficiently handle various packaging formats. According to a recent report from the Packaging Machinery Manufacturers Institute (PMMI), nearly 70% of manufacturers consider the ability to quickly switch between product types and pack sizes a crucial factor in their production strategy. This adaptability not only streamlines the packaging process but also enhances responsiveness to market trends and customer preferences.

Moreover, the versatility of case packers extends to the range of materials and products they can accommodate. These machines can easily manage different container shapes, sizes, and types, from bottles and jars to cartons and cans, providing a cohesive solution for diverse packaging needs. Research by Freedonia Group highlights that manufacturers utilizing automated case packing systems can increase their production speeds by up to 50%, thus significantly reducing turnaround times and improving overall operational efficiency. With the ongoing evolution of product offerings, having a packaging solution that can adapt and evolve is no longer an option but a necessity for companies striving for competitive advantage.

Related Posts

-

What is a Case Packer and How Does it Work in Packaging Automation

-

2025's Best Packaging Equipment: Top Innovations Transforming the Industry

-

2025 Top 5 Food Bagging Machines You Need to Know About

-

2025 How to Choose the Best Packer Machine for Your Business Needs

-

2025 Top 10 Packer Machines Revolutionizing Packaging Efficiency with 20 Percent Faster Processing

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights